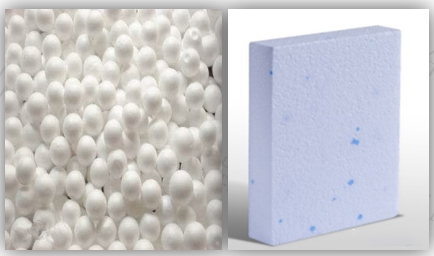

Polystyrene board (EPS) - standardized thermal insulation board made of disposable polystyrene beads as raw material, pre-foaming, maturing, molding, aging, cutting and other processes. It is characterized by light weight, heat insulation, sound insulation, low temperature resistance, long application time and mature technology.

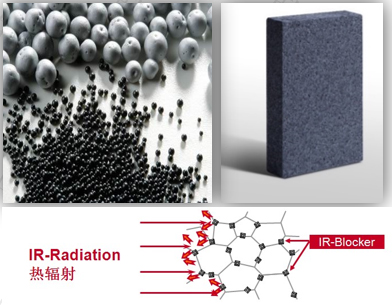

Graphite Polystyrene Sheet (SEPS) - A standardized thermal insulation sheet made of disposable polystyrene modified with nano-sized flake graphite particles, through the process of pre-foaming, maturing, molding, aging, cutting, and so on. The graphite particles dispersed in the polystyrene have the effect of reflecting infrared rays, which can effectively reduce the long-wave heat radiation, and compared with the ordinary white EPS, the thermal conductivity is lower, and the flame retardant property is more stable.

Pre-expansion

Pre-expanding machine expands the raw material particles by 40-60 times through steam, forming discontinuous honeycomb air holes inside the particles, and the pre-expanded particles are transported to the ripening silo through the pipeline.

Ripening

After pre-firing, the EPS pellets are under negative pressure inside, there is still a certain amount of pentane and water vapor, and there is also condensation on the surface. Entering the maturation bin ventilation maturation, so that pentane and water further volatilization, and air into the bubble.

Molding

The cooked EPS pellets enter the mold of the molding machine through the material gun, steam is introduced and the pellets are softened by heat and expanded to form a block.

Aging

After demolding, the surface of the EPS board products is humid, and the temperature difference between the inside and outside is large, the condensation of steam and residual blowing agent in the bubble holes will lead to a partial vacuum, and the large board is sensitive to pressure. Through aging, the water and blowing agent in the board continues to evaporate, which is conducive to the board's flame retardant properties and dimensional stability.

Cutting and Packing

Molded products produced in block form are cut using an electric wire, cut to the required thickness, and packaged in a thermoplastic film packaging machine.

Post time: Aug-09-2023