We see a wide variety of foam products every day, from automotive parts to household appliances, and the shape of the foam can be customized according to the customer's needs. So what is the principle of foam molding machine?

Foam molding machine is a material plastic parts molding machine which is a machine to make foam into the shape as per the customer's requirement. It is an automated molding machine which can run 24 hours, 7 days with very high productivity. It works on the principle of using compressed air to fuse the raw materials of the foam and then mold it into the desired shape as per the requirement of the customer.

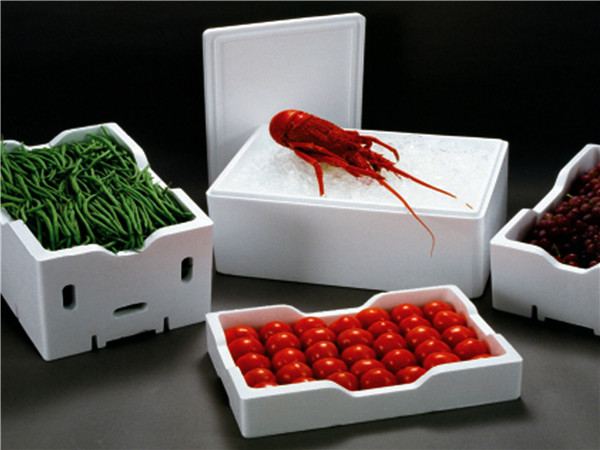

Foam molding machine has a wide range of industrial applications, it can be used to produce a variety of foam products, such as automotive parts, household appliances, bags, furniture, tools and so on. Since it can produce high quality products, it is becoming more and more widely used in industry.

Foam molding machine is a very practical machine, it can meet the individual needs of customers, and the production efficiency is very high, it has an important position in the industry. Its appearance makes our life more convenient and provides more possibilities for industry.

With the progress of science and technology, foam molding machine is also getting more and more attention, which is a kind of mechanical equipment using high pressure gas for molding. Foam molding machine has many features, here are a few:

Foam forming machine has high molding efficiency, can be completed in a shorter time, greatly reducing the molding time, can meet the needs of mass production. In addition, the foam molding machine also has good corrosion resistance, can resist the erosion of various corrosive gases, greatly extending its service life. Foam molding machine operation is simple, can realize automatic operation, do not need too many operators, can reduce costs.

Foam molding machine has an important position in the molding industry, it can meet the needs of large-scale production, has a high molding efficiency, good corrosion resistance, simple operation, and can be automated, is a very practical mechanical equipment. Its appearance also makes the molding industry achieve great development, and also makes a positive contribution to the development of society.

Foam molding machine is a special kind of mechanical equipment, which attracts many consumers with its simple structure, efficient technology and reliable performance, and is widely used. Its appearance undoubtedly facilitates industrial production and consumers and brings us a lot of convenience.

Foam molding machine adopts advanced technology, which can effectively control its processing quality and ensure certain precision with reliable performance. Secondly, it adopts a simple operation structure, which is easy and convenient to operate and can meet a variety of processing requirements. In addition, its processing can save a lot of energy, which is conducive to protecting the environment and meets the requirements of green production.

Post time: Jul-31-2023