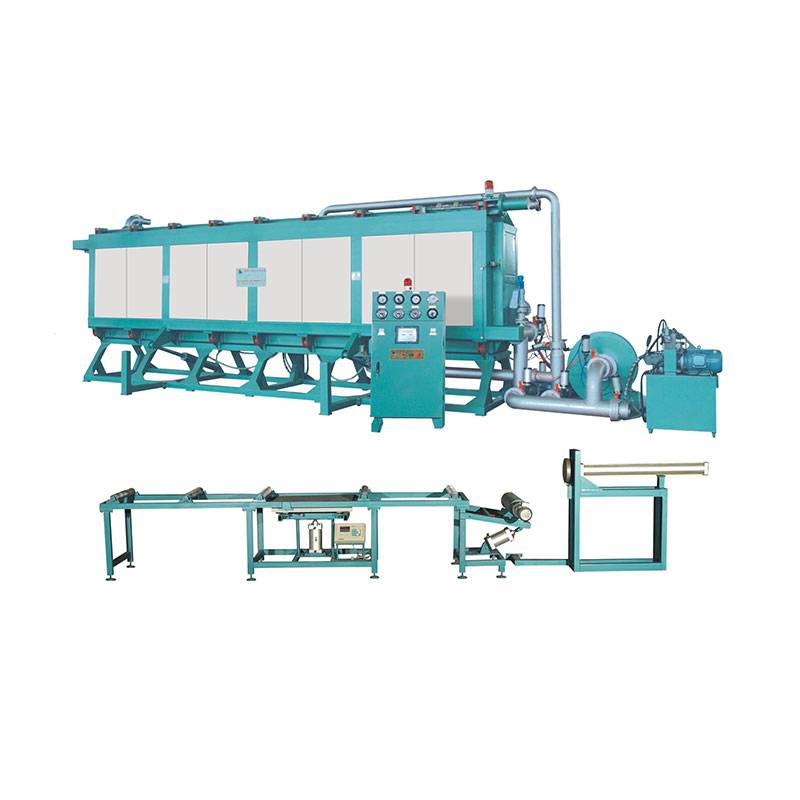

18 Years Factory Epp Production Line - High efficient Automatic EPS Shape Molding Machine – WELLEPS

18 Years Factory Epp Production Line - High efficient Automatic EPS Shape Molding Machine – WELLEPS Detail:

Main Feature

- Machine use strong structure, normally use 20 mm thickness Q345 high strength steel plate. Machine plate and pipe system with hot galvanized, that it is not easy to get rust

- Machine adopts the best size calculation and clear pipe system, ensures a rapid pressurization and reduce pressure process. Machine use steam system balancing valve and pressure sensor control, PID control so the machine have accurate heating and energy saving, short heating time, rapidly improve the running speed of the equipment

- Machine use PLC control, touch screen operation, the system with self protection and alarm system, electrical components adopt international famous brand, guarantee the safe operation

- Machine has made great improvement on seals, all fast connector using liquid sealant to seal, use nylon tube instead of the traditional PU tube, prolong the service life and can effectively prevent the air leakage, with more energy savings

- Machine vacuum use spray cooling device, machine working mainly use vacuum cooling then water cooling. That the machine working faster and the product moisture content of less than 8%

- Welleps Machine with double hopper, can produce two different density product at one time, Hopper was special designed, it can keep pressure very well.

Send machine to customers:

Machine in customers’ factory:

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for 18 Years Factory Epp Production Line - High efficient Automatic EPS Shape Molding Machine – WELLEPS , The product will supply to all over the world, such as: Maldives, Malaysia, Comoros, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

Write your message here and send it to us