High efficient Automatic EPS Shape Molding Machine

Technical Data

| Item | Unit | Type | ||||||

| PSZ100JN | PSZ120JN | PSZ140JN | PSZ160JN | PSZ175JN | PSZ180JN | |||

| Mould Dimension | mm | mm | 1000*800 | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | 1800*1600 |

| Max Product Dimension | mm | mm | 800*600

*330 |

1000*800

*330 |

1200*1000

*330 |

1400*1100

*330 |

1550*1200

*330 |

1610*1400

*330 |

| Stroke | mm | 190-1400 | 190-1400 | 190-1400 | 210-1410 | 210-1410 | 210-1410 | |

| Steam | Entry | mm | DN65 | DN65 | DN10 | DN100 | DN100 | DN100 |

| Consumption | kg/cycle | (8-10T)Steam of 1T material 每吨原料消耗8-10吨蒸汽 | ||||||

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 40-120 | 40-138 | 50-150 | 55-180 | 60-190 | 80-200 | |

| Compressed Air | Entry | mm | DN40 | DN40 | DN40 | DN50 | DN50 | DN50 |

| Consumption | m3/cycle | 1.2 | 1.2 | 1.2 | 1.4 | 1.5 | 1.5 | |

| Vacuum Pump Capacity | m3/h | 165 | 165 | 230 | 280 | 280 | 280 | |

| Power | Kw | 11 | 11 | 12.5 | 16.5 | 16.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1640

*2700 |

4500*1840

*2900 |

4600*2140

*3100 |

5000*2300

*3100 |

5000*2450

*3500 |

5000*2610

*3800 |

| Weight | kg | 4500 | 5200 | 5700 | 7000 | 7500 | 8000 | |

| Cycle Time | s | 60-90 | 60-100 | 60-120 | 70-130 | 70-130 | 80-140 | |

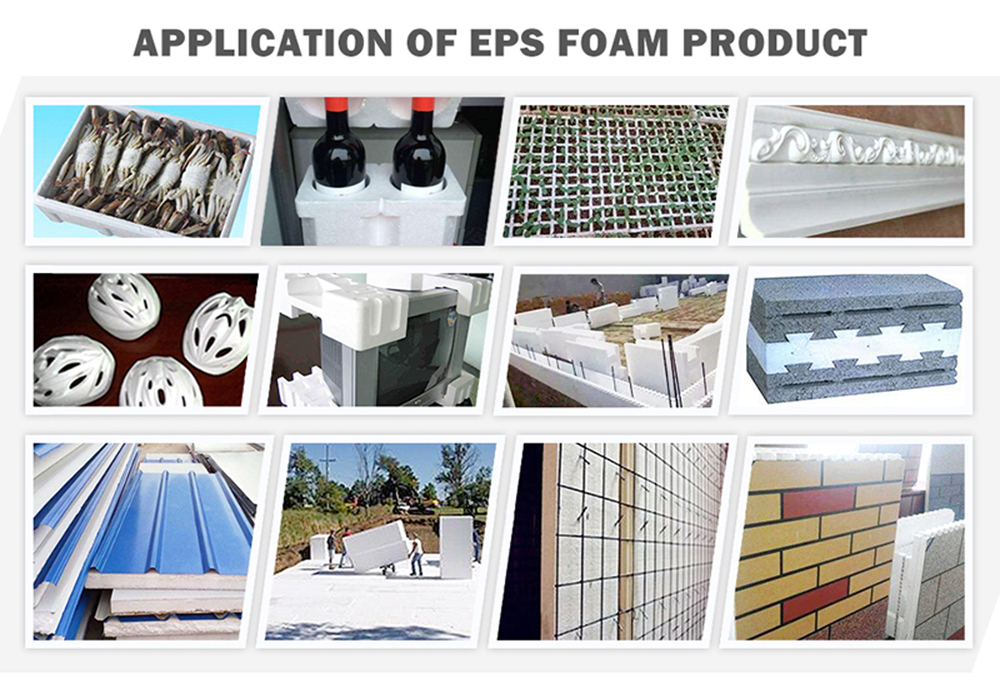

Application Field:

EPS products widely industry such as vegetable and fish box, electric parts package, wall and roof indulation, house decoration and etc.

Products:

Main Feature:

1.Machine use strong structure, normally use 20 mm thickness Q345 high strength steel plate. Machine plate and pipe system with hot galvanized, that it is not easy to get rust

2.Machine adopts the best size calculation and clear pipe system, ensures a rapid pressurization and reduce pressure process. Machine use steam system balancing valve and pressure sensor control, PID control so the machine have accurate heating and energy saving, short heating time, rapidly improve the running speed of the equipment

3.Machine use PLC control, touch screen operation, the system with self protection and alarm system, electrical components adopt international famous brand, guarantee the safe operation

4.Machine has made great improvement on seals, all fast connector using liquid sealant to seal, use nylon tube instead of the traditional PU tube, prolong the service life and can effectively prevent the air leakage, with more energy savings

5.Machine vacuum use spray cooling device, machine working mainly use vacuum cooling then water cooling. That the machine working faster and the product moisture content of less than 8%

6.Welleps Machine with double hopper, can produce two different density product at one time, Hopper was special designed, it can keep pressure very well.

Machine in customers' factory: