Factory selling Cutting Wires - Thermocol Foam Moulding Machine Fruit/Fish Boxes Packaging Making Molding Machine – WELLEPS

Factory selling Cutting Wires - Thermocol Foam Moulding Machine Fruit/Fish Boxes Packaging Making Molding Machine – WELLEPS Detail:

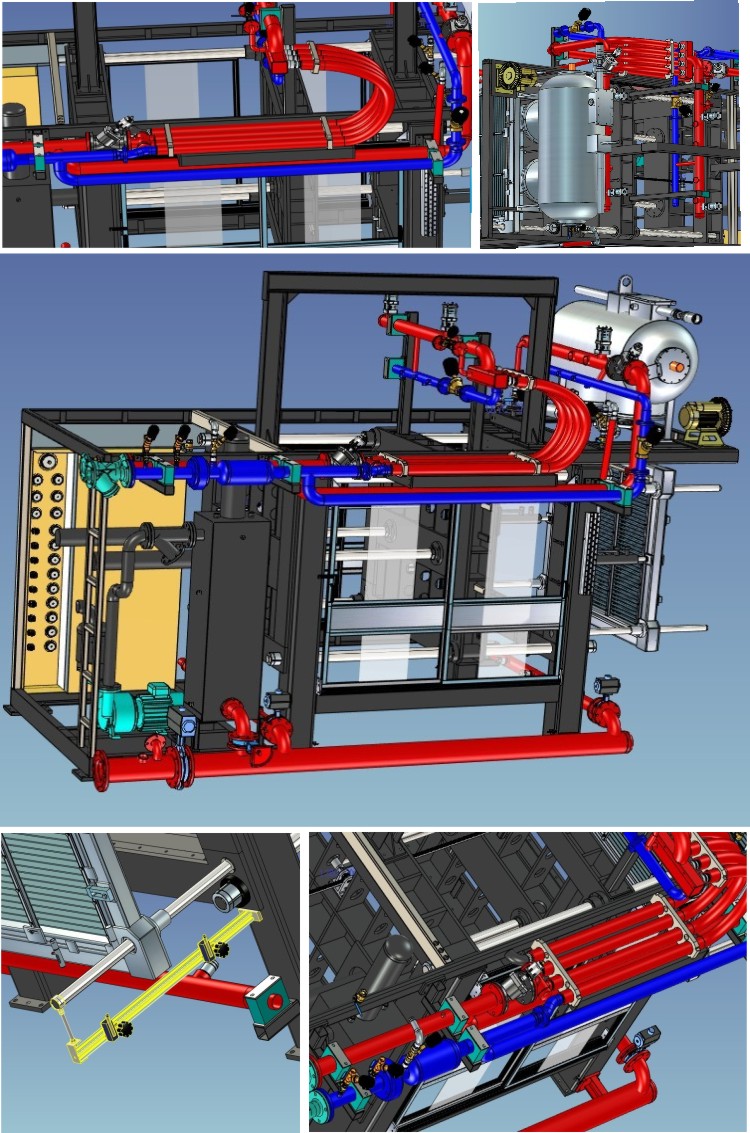

Main advantage:

1. Use servo drive system, the machine can work very stable.

2. Use two side steam and vacuum, machine works more efficiently.

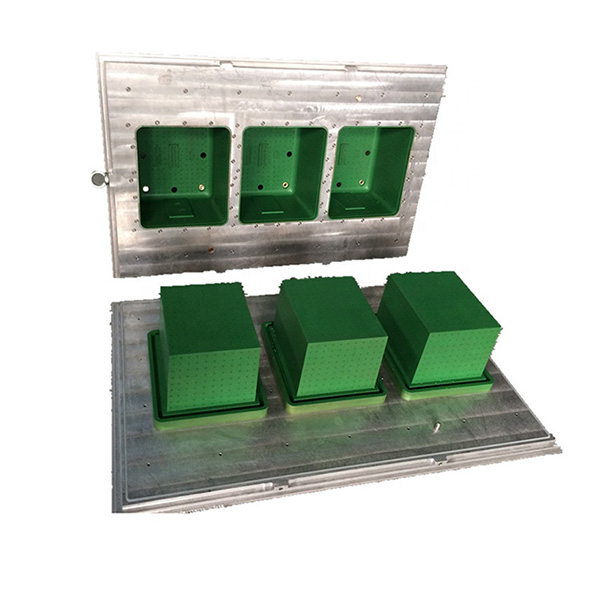

3. With special design ejectors shelf for easy to install the moulds.

Features of eps foam box machine:

1.Equipment body use the high strength steeel welded together, after the tempering process, sandblasting

processing, to ensure the machne have strong structure, not get rust and increae the machine’s working life.

2.Equipment adopts Mitsubishi PLC(programmable controller) and touch screen control. The whole

production process is working automatically.

3.Macine with high-pressure feed system, feeding mould fast,machine can install 36 pcs filling guns.

4.Machine with wacuum system, it can make the cycle time shorter ,cooling much faster ,and reduce the

moisture content of products, so that products moisture content of 8% or even less.

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not

damage the products when ejecting.

6.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mouled even, low noise and

energy saving,etc.

| Item | PSZS-1412 | PSZS-1816 | PSZS-2018 | ||

| Mould Dimension | mm | 1400*1200 | 1850*1600 | 2000*1800 | |

| Rear window dimensions | mm | 1250*1050 | 1700*1450 | 1750*1650 | |

| Effective forming area | mm | 1200*1000 | 1500*1250 | 1650*1450 | |

| Max Produce Size | mm | 400 | 400 | 400 | |

| Steam | Pipe connect | DN | 100 | 100 | 100 |

| Die connect | DN | 40/6 | 40/8 | 40/8 | |

| Pressure | kg/cm² | <5 | <5 | <5 | |

| Consumption | kg/cycle | 3-12 | 3-15 | 3-18 | |

| Air | Pipe connect | DN | 80/2 | 80/2 | 80/4 |

| Pressure | kg/cm² | <4 | <4 | <4 | |

| Cooling Water | Pipe connect | DN | 80 | 80 | 80 |

| Die connect | DN | 25/2 | 25/3 | 25/3 | |

| Pressure | kg/cm² | <3 | <3 | <3 | |

| temperature | ℃ | 45-55 | 45-55 | 45-55 | |

| Single Vacuum | Motor | KW | 5 | 7.5 | 7.5 |

| Connect | DN | 100 | 100 | 100 | |

| Drain | DN | 40 | 40 | 40 | |

| Dain water | DN | 25 | 25 | 25 | |

| Vacuum Center | Connect | DN | 100 | 100 | 100 |

| Drainage | Drain Outlet | Φ | 159 | 159 | 159 |

| Mould Outlet | DN | 40/3 | 40/4 | 40/4 | |

| Hydralic system | Motor | KW | 7.5 | 11 | 11 |

| Pump | L/min | 31/97 | 31/116 | 31/116 | |

| Lock power | T | 24 | 37 | 46 | |

| Open-close cylinder | mm | 100*2 | 125*2 | 140*2 | |

| Demould cylinder | mm | 50*2 | 50*2 | 50*2 | |

| Hopper | Volume | m³ | 0.3 | 0.4 | 0.4 |

| Motor | KW | 1.5 | 2.2 | 2.2 | |

| Material hole | Pieces | 22 | 44 | 44 | |

| Electric Load | KW | 16.5 | 20.7 | 20.7 | |

| Overall Dimension | mm | 4800*3320*2800 | 4800*3600*3200 | ||

| Weight | kg | 7200 | 8000 | ||

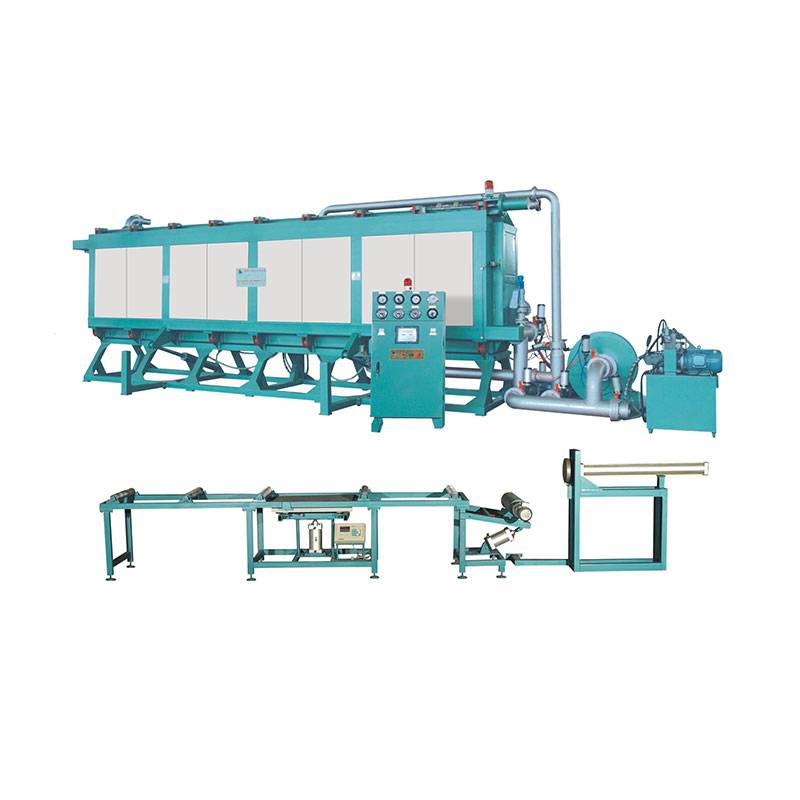

EPS foam Machine is widely used to make EPS foam fish box

EPS foam packages for transpotation

EPS ICF blocks for construction building

EPS foam decoration cornice ceilling,etc.

Services:

1. Value clients, guarantee equipment quality and answer clients’ questions anytime and anywhere.

2. Customizing machines according to clients’ inquiry , such as different design, different brand parts, different colors, more function,etc.

3. Engineers go to clients’ factory in time for installation , training and trial production .

4. Lifetime technical service support.

Packaging & Shipping :

Packing: standard exporting package

Shippingport: shanghai/Ningbo

If you are interested in any of our products or would like any support from us about yourfactory or any others, please feel free to contact us.

We are looking forward to building longwell and friendly business relationships with clients from all over the world.

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Factory selling Cutting Wires - Thermocol Foam Moulding Machine Fruit/Fish Boxes Packaging Making Molding Machine – WELLEPS , The product will supply to all over the world, such as: Juventus, UK, Egypt, Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.