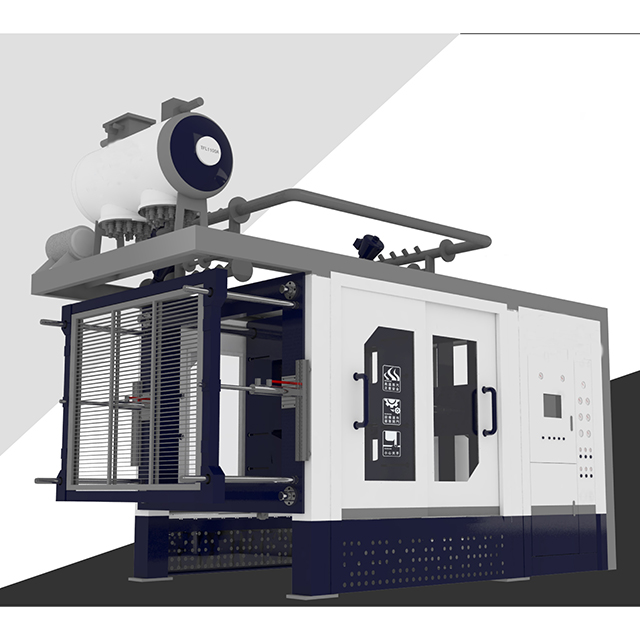

Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS

Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS Detail:

Main Advantage

Eps styrofoam boxes making machine products are widely used in industries such as vegetables and fish boxes, electrical parts packaging, wall and roof insulation, and house decoration.

1. Machine with PLC control work complete automatically.

2. Use good quality parts for the machine work very stable.

3. Use strong structure, machine work smoothly.

4. Produce good quality EPS products, the customers will win in the competitive market.

Machine Introduction

1.Equipment body use the high strength steel welded together, after the tempering process, sandblasting processing, to ensure the machine have strong structure, not get rust and increase the machine’s working life

2.Equipment adopts Mitsubishi PLC ( programmable controller )and Schneider touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast, machine can install 36 pcs filling guns

4.Machine with vacuum system, it can make the cycle time shorter, cooling much faster, and reduce the moisture content of products, so that products moisture content of 8% or even less

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting

6.Machine pipe system use balancing valve and pressure sensor control, PID control so that heat penetrates quickly, lower energy consumption

7.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mould even, low noise and energy saving, etc

Technical Data

| Item | Unit | Type | |||

| PSZ120T | PSZ160T | PSZ180T | |||

| Mould Dimension | mm | mm | 1200*1000 | 1600*1350 | 1800*1600 |

| Max Product Dimension | mm | mm | 1050*850*330 | 1420*1200*330 | 1600*1400*330 |

| Stroke | mm | 210-1360 | 270-1420 | 220-1370 | |

| Steam | Entry | mm | DN65 | DN80 | DN80 |

| Consumption | kg/cycle | (12-15T)Steam of 1T material | |||

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 45-130 | 50-140 | 55-190 | |

| Compressed Air | Entry | mm | DN40 | DN50 | DN50 |

| Consumption | m3/cycle | 1.3 | 1.4 | 1.5 | |

| Vacuum Pump Capacity | m3/h | 165 | 280 | 280 | |

| Power | Kw | 11 | 16.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1840*2900 | 5000*2300*3400 | 5100*2550*3700 |

| Weight | kg | 4600 | 5700 | 6200 | |

| Cycle Time | s | 60-100 | 100-180 | 120-190 | |

Applications

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS , The product will supply to all over the world, such as: Ecuador, Bogota, Jamaica, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!