100% Original Sandwich Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS

100% Original Sandwich Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS Detail:

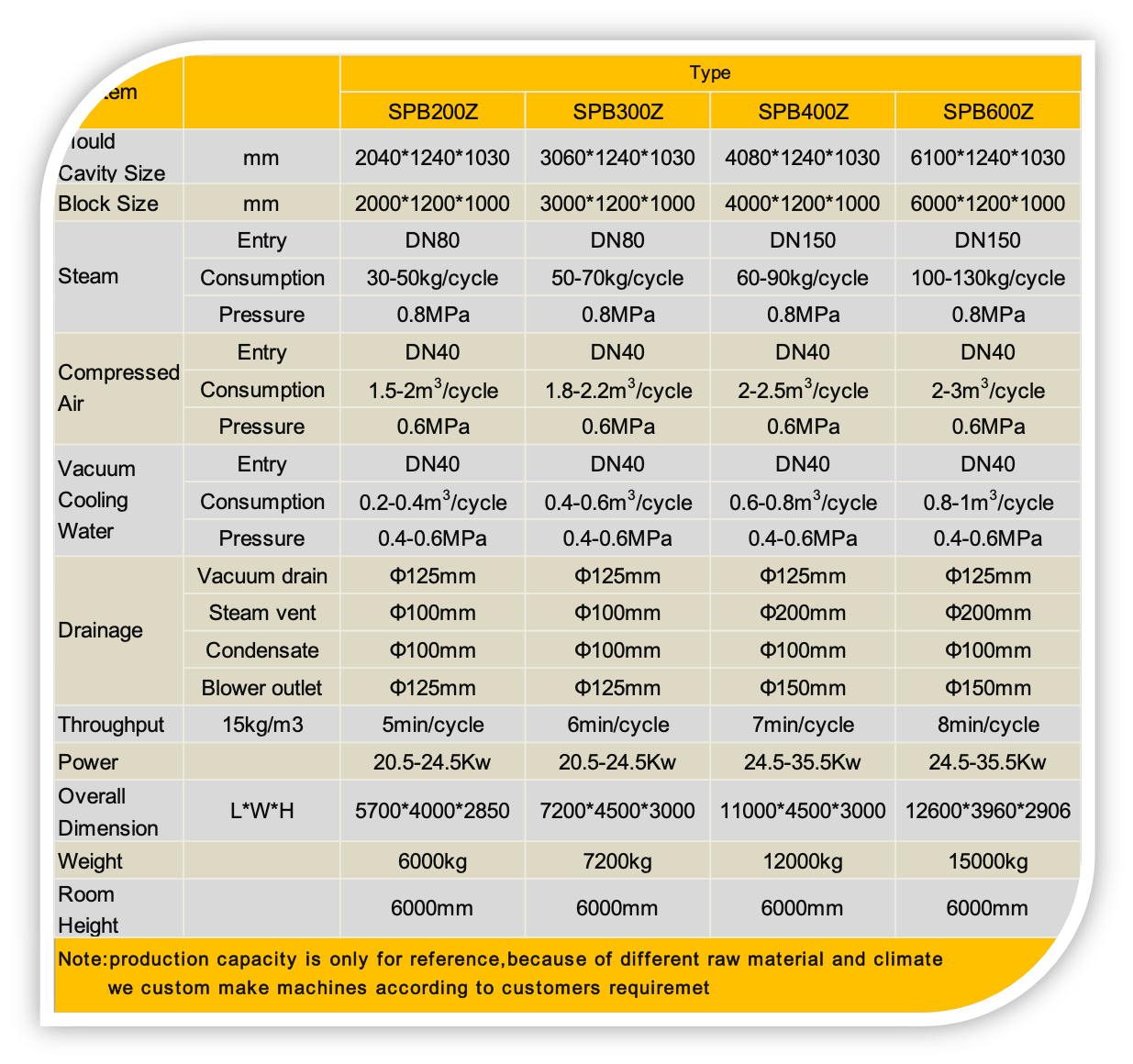

Main Features

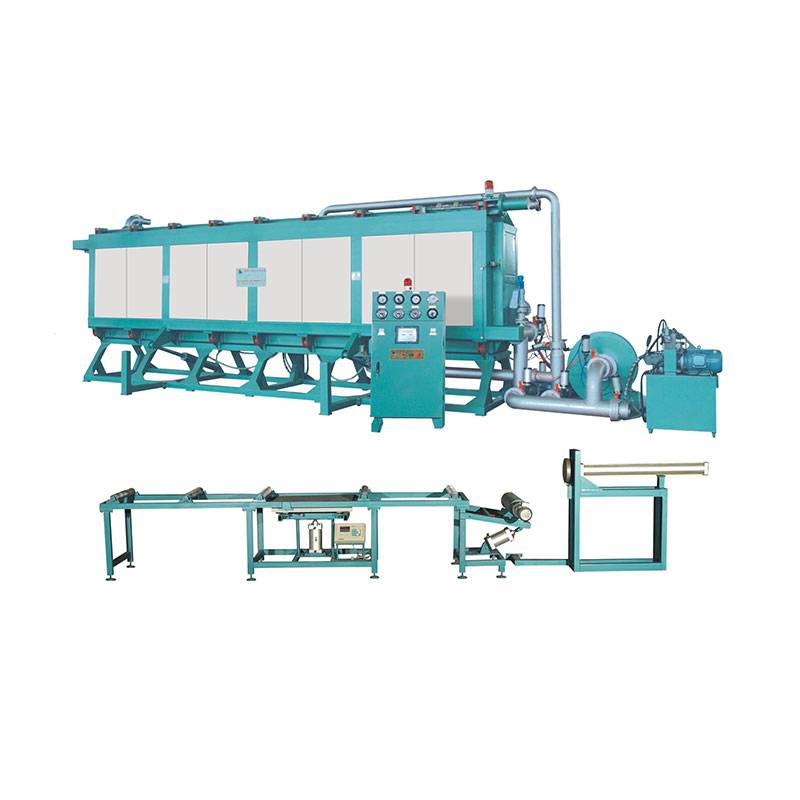

1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power and energy saving design. Produced blocks have excellent cohesiveness, low moisture content, to ensure every customer’s satisfy.

4. Adopt PLC and touch screen control system, equipped with material level sensor can realize automatic control of feeding, equipped with foam pressure sensor control cooling time automatically.

5. Machine use good quality electrical, pneumatic components, valves and other parts. And the parts with international standard, so customer is easy to find replacement at local.

6. Machine adopts hydraulic pressure station to be the center control system. Use hydraulic open door, ejector de-mould and locking, guarantee the machine running smoothly, stable performance.

EPS block Machine in workshop :

EPS block Machine loading container:

EPS Products:

Remarks:

Above equipment has FT and ZT model

FT type is air-cooling type, cooling without c vacuum system

FT type products thickness is 600 mm.

ZT products maximum thickness is 1000 mm.

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for 100% Original Sandwich Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS , The product will supply to all over the world, such as: New Orleans, Jakarta, Florida, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.