EPS Electrical Packaging Moulding Machine

Main Advantage

1.Equipment body use the high strength steel welded together, after the tempering process, sandblasting processing, to ensure the machine have strong structure, not get rust and increase the machine’s working life

2.Equipment adopts Mitsubishi PLC ( programmable controller )and Schneider touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast, machine can install 36 pcs filling guns

4.Machine with vacuum system, it can make the cycle time shorter, cooling much faster, and reduce the moisture content of products, so that products moisture content of 8% or even less

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting

6.Machine pipe system use balancing valve and pressure sensor control, PID control so that heat penetrates quickly, lower energy consumption

7.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mould even, low noise and energy saving, etc

Technical Data

| Item | Unit | Type | |||||

| PSZ100T | PSZ120T | PSZ140T | PSZ160T | PSZ175T | |||

| Mould Dimension | mm | mm | 1000*800 | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 |

| Max Product Dimension | mm | mm | 850*650*330 | 1050*850*330 | 1220*1050*330 | 1420*1200*330 | 1550*1250*330 |

| Stroke | mm | 210-1360 | 210-1360 | 270-1420 | 270-1420 | 270-1420 | |

| Steam | Entry | mm | DN65 | DN65 | DN80 | DN80 | DN80 |

| Consumption | kg/cycle | (12-15T)Steam of 1T material | |||||

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 45-130 | 45-130 | 50-140 | 50-140 | 55-190 | |

| Compressed Air | Entry | mm | DN40 | DN40 | DN40 | DN50 | DN50 |

| Consumption | m3/cycle | 1.3 | 1.3 | 1.4 | 1.4 | 1.5 | |

| Vacuum Pump Capacity | m3/h | 165 | 165 | 250 | 280 | 280 | |

| Power | Kw | 11 | 11 | 14.5 | 16.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1640

*2700 |

4500*1840

*2900 |

4600*2140

*3100 |

5000*2300

*3400 |

5000*2550

*3700 |

| Weight | kg | 4100 | 4600 | 4900 | 5700 | 6200 | |

| Cycle Time | s | 60-90 | 60-100 | 60-150 | 100-180 | 120-190 | |

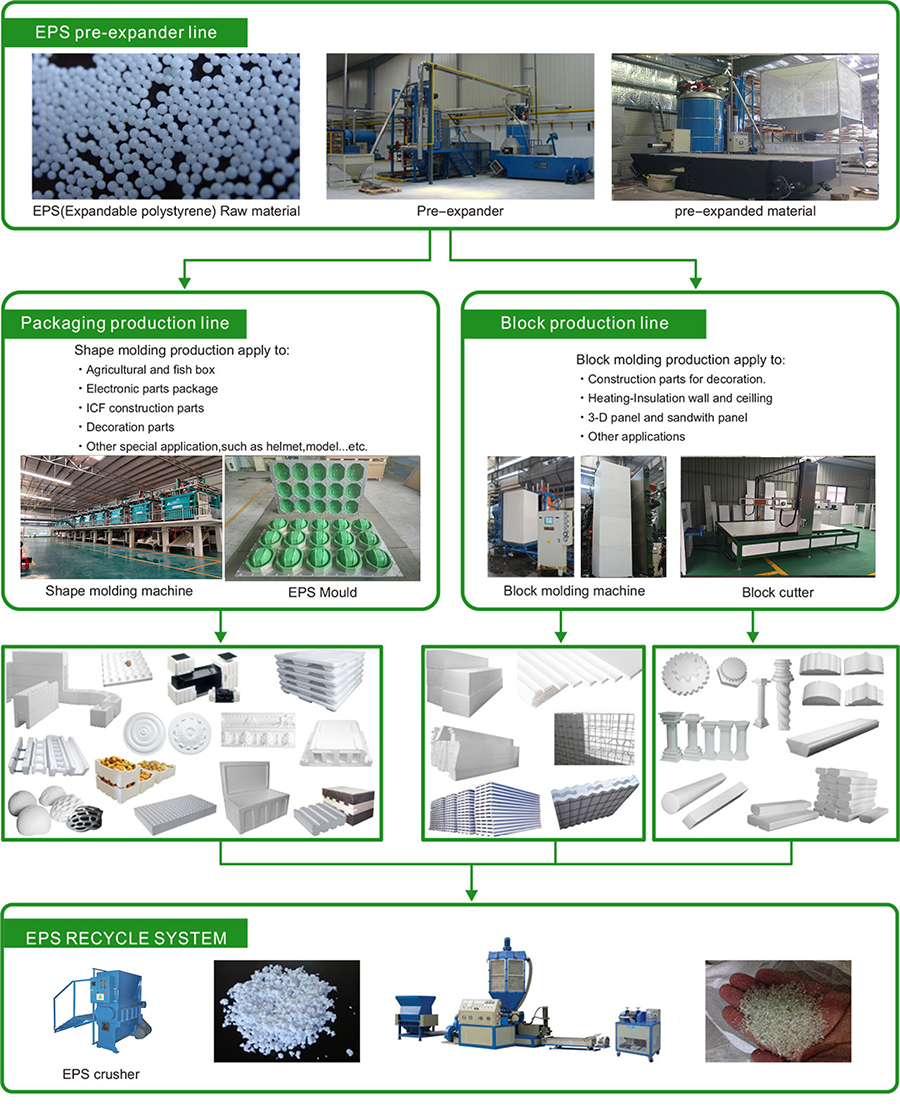

Production process flow