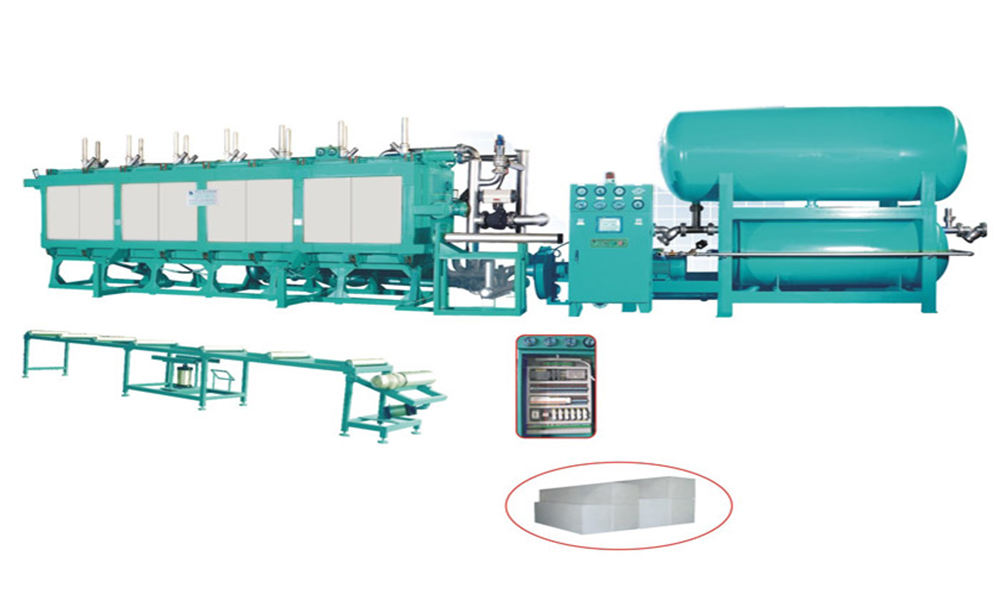

factory Outlets for Etpu Molding - Automatic EPS Block Molding Machine With Air Cooling – WELLEPS

factory Outlets for Etpu Molding - Automatic EPS Block Molding Machine With Air Cooling – WELLEPS Detail:

Main Features

1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power and energy saving design. Produced blocks have excellent cohesiveness, low moisture content, to ensure every customer’s satisfy.

4. Adopt PLC and touch screen control system, equipped with material level sensor can realize automatic control of feeding, equipped with foam pressure sensor control cooling time automatically.

5. Machine use good quality electrical, pneumatic components, valves and other parts. And the parts with international standard, so customer is easy to find replacement at local.

6. Machine adopts hydraulic pressure station to be the center control system. Use hydraulic open door, ejector de-mould and locking, guarantee the machine running smoothly, stable performance.

Technical Data

| Item | Type | ||||

| PSB200TF | PSB300TF | PSB400TF | PSB600TF | ||

| Mould Cavity Size | mm | 2040*1240*580 | 3060*1240*630 | 4080*1240*630 | 6080*1240*630 |

| Block Size | mm | 2000*1000*560 | 3000*1200*600 | 4000*1200*630 | 6000*1200*600 |

| Steam | Entry | DN80 | DN80 | DN100 | DN150 |

| Consumption | 18-25kg/cycle | 25-35kg/cycle | 40-50kg/cycle | 55-65kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN40 | DN40 | DN50 | DN50 |

| Consumption | 1-1.2m3/cycle | 1.2-1.6m3/cycle | 1.6-2m3/cycle | 2-2.2m3/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Vacuum drain | ||||

| Steam vent | Φ100mm | Φ150mm | Φ150mm | Φ150mm | |

| Condensate | |||||

| Blower outlet | Φ125mm | Φ125mm | Φ150mm | Φ150mm | |

| Throughput | 15kg/m3 | 5-12min/cycle | 6-15min/cycle | 7-18min/cycle | 8-18min/cycle |

| Power | 7Kw | 8Kw | 9.5Kw | 9.5Kw | |

| Overall Dimension | L*W*H | 3800*2000*2100 | 5100*2300*2100 | 6100*2300*2200 | 8200*2500*3100 |

| Weight | 3500kg | 5000kg | 6500kg | 9000kg | |

| Room Height Required | 6000mm | 6000mm | 6000mm | 6000mm | |

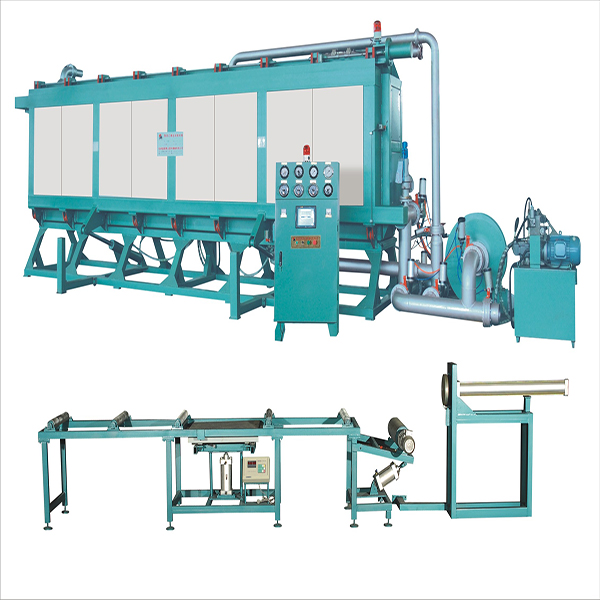

Products

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for factory Outlets for Etpu Molding - Automatic EPS Block Molding Machine With Air Cooling – WELLEPS , The product will supply to all over the world, such as: France, Austria, Burundi, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.