Featured

-

Big Discount Diesel Oil Steam Boiler - SPB200TZ-600TZ EPS Block Molding Machine – WELLEPS

Machine Introduction EPS Block Molding Machine is used to make EPS blocks, then cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc Main Features 1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine o... -

Wholesale Supplier Eps Production Line - Energy saving eps foam system recycle styrofoam machine – WELLEPS

Our EPS recycling system consists of Crusher, Deduster and Mixer. The crushing machine smashes wasted EPS products or EPS scraps into granules, then 1t goes through the de-duster to sieve and remove the dust. After sieving and dedusting, the recycling material is mixed with virgin material according to the pre defined proportion and can be used in both Shape and Block Molding Machines Item FS300 FS320 Capacity 25-30m3/h 25-30m3/h Diameter of Beads 4-12mm 4-12mm Connected Load 14... -

-

-

-

-

-

-

-

-

-

Wholesale Dealers of Steam Accumulator - SPY7090120 Continuous Pre-expander – WELLEPS

Main Features 1.Feeding, expander, filtrating, crushing, transport to silos automatically 2.With first and second expansion, the first time filling adopt frequency conversion feeding device, guarantee the stability of feeding 3.Uniform foaming, foam density range is 6-35g/l 4.Material barrel inside and outside, fluidized bed dryer made of stainless steel, in order to maintain the durable use and stable performance 5.Electrical protection device 6.Adopt Japanese reducing valve Techni... -

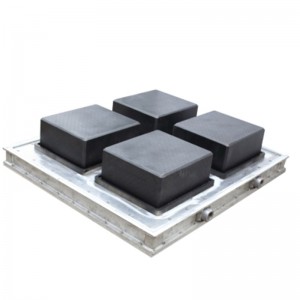

One of Hottest for Water Tower - Best Quality EPS Mould In China – WELLEPS

Main Features We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less t...