Featured

-

Factory wholesale Polystyrene Foam Equipment - Automatic Continuous Polystyrene EPS Foam Cup Making Machine – WELLEPS

Main Features 1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing . 2. Light weight, good rigidity and well heat isolation. 3. The machine holds many merits such as high foaming times, high producing efficiency, low steam consumption, low cost and different model products are made at same time. 4. Pipes and tubes of the transferring system are all made from stainles... -

-

-

-

-

-

Manufacturer of Fast Change Filling Guns. - Best Quality Automatic EPP Shape Molding Machine – WELLEPS

EPP(Expanded Polypropylene) EPP(Expanded Polypropylene) is a kind of high performance crystalline polymer/gas composite materials, with its excellent performance to become the fastest growing environmental protection and insulation materials. Main Performance 1.Energy absorption: because the EPP products have special bubble pore structure, it can absorb the energy from outside efficiently, and can anti-press very well. 2.Recycling: EPP products good flexibility can be used repeatedly, not eas... -

-

-

-

Best Price for Epp Foaming Tool For Auto Car Seat - Automatic EPS Block Molding Machine With Air Cooling – WELLEPS

Main Features 1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life. 2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency. 3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power an... -

-

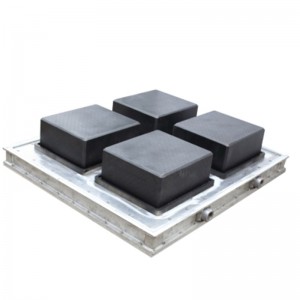

2019 High quality Etpu Shape Molding Machine - Best Quality EPS Mould In China – WELLEPS

Main Features We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less t...