Featured

-

-

OEM Customized Icf Mould - New Type Fast Mould Change EPS Shape Molding Machine – WELLEPS

Technical Data Item Unit Type/Technical Data PSZ1214EP PSZ1218EP Mould Dimension mm 1500*1300 1950*1300 Max.Product Dimension mm 1400*1200*330 1800*1200*330 Minimum Mould Thickness mm 220 220 Stroke mm 210-1450 210-1450 Mounting Interface Raw material / DN40 DN40 Steam / DN100 DN100 Compressed air / DN65 DN65 Cooling water / DN80 DN80 Drainage / DN150 DN150 Ventilation / DN80 D... -

High Quality Fish Box Machine - EPS Styrofoam Thermocol Plate Disposable Plastic Foam Cup Tray Dish Food Container Making Machine – WELLEPS

Main Features 1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing . 2. Light weight, good rigidity and well heat isolation. 3. The machine holds many merits such as high foaming times, high producing efficiency, low steam consumption, low cost and different model products are made at same time. 4. Best quality,Resonable price Technical Data Main perfor... -

factory customized High Pressure Air Compressor - High efficient Automatic EPS Shape Molding Machine – WELLEPS

Technical Data Item Unit PSZ100T PSZ140T PSZ175T Moule Dimension mm 1000*800 1400*1200 1750*1450 Max Product Dimension mm 850*650*330 1220*1050*330 1550*1250*330 Stroke mm 210-1360 270-1420 270-1420 Cooling Water Entry mm DN65 DN65 DN65 Consumption kg/cycle 45-130 50-140 55-190 Compressed Air Entry mm DN40 DN40 DN50 Consumption m³/cycle 1.3 1.4 1.5 Vacuum Pump Capacity m³/h 165 250 280 Power kw 11 14.5 16.5 Overall Dimension L*W*H mm 4500*1640*2700 4600*214... -

8 Year Exporter Epp Lego Mould - Automatic Continuous Polystyrene EPS Foam Cup Making Machine – WELLEPS

Main Features 1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing . 2. Light weight, good rigidity and well heat isolation. 3. The machine holds many merits such as high foaming times, high producing efficiency, low steam consumption, low cost and different model products are made at same time. 4. Pipes and tubes of the transferring system are all made from stainles... -

OEM/ODM Supplier Eps Concrete Machine Mould Car - ICF machine for building insulation – WELLEPS

Main Features 1. Use proportional steam valve for save steam and heat accurately. 2. Can install the filling guns and ejectors on the ground, can save time to install moulds. 3. Special designed hopper can control the material filling more accurately to ensure make good quality products. 4. Use stainless steel oil pipes to keep machine running stable and not leak oil. 5. Lock moulds same as Germany machine, can keep high pressure in the moulds. 6. All pipe and mould plate coated with zin... -

-

-

-

-

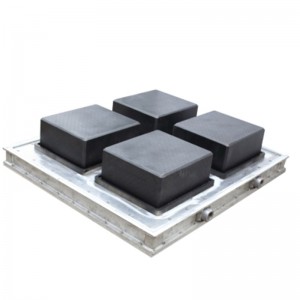

factory low price Screw Air Compressor - Best Quality EPS Package Moulds – WELLEPS

We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm. Mould coated w... -

Newly Arrival Epp Mold - Best Quality EPS Mould In China – WELLEPS

Main Features We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less t... -

High definition Sandwich Wall Panel Making Machine - Best Quality EPS Package Moulds – WELLEPS

We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm. Mould coated w...