Featured

-

-

-

Manufacturer for Eps Mould Factory - Best Quality EPS Mould In China – WELLEPS

Main Features We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less t... -

-

Factory For Screw Compressor - Best Quality Automatic EPS Batch Pre-expander – WELLEPS

Main Features 1.Feeding, expander, filtrating, transport to silos automatically 2.Steam system controlled by pressure reducing valve and Angle seat valve, to achieve accurate heating 3.Feeding system adopts electronic weighing system, material level sensor control, so as to control capacity of foaming materials, to ensure that the foam bead evenly 4.Use PLC controller and touch screen, achieve precise automatic operation 5.Feed barrels made of stainless steel. Electrical components, valves a... -

-

-

factory low price Ejector - Pet Dog Chew Ball EPP Foam Material Pet Playing Dog Toy Solid Chew Dog Toy Ball – WELLEPS

Ball toys are more mobile than other toys of any shape, and because of its strong elasticity and mobility, it will generate a uncertainty of direction change. Therefore, it is very attractive for dogs, which are good at capturing moving targets. Dogs are more willing to chase. Their running route must be irregular, so ball toys, Compared with other shapes of toys, it can attract the dog’s attention and arouse the dog’s interest in chasing. Product Name Pet Playing/Training... -

New Arrival Wholesale Wall Insulation Panel - Energy saving eps foam system recycle styrofoam machine – WELLEPS

Our EPS recycling system consists of Crusher, Deduster and Mixer. The crushing machine smashes wasted EPS products or EPS scraps into granules, then 1t goes through the de-duster to sieve and remove the dust. After sieving and dedusting, the recycling material is mixed with virgin material according to the pre defined proportion and can be used in both Shape and Block Molding Machines Item FS300 FS320 Capacity 25-30m3/h 25-30m3/h Diameter of Beads 4-12mm 4-12mm Connected Load 14... -

-

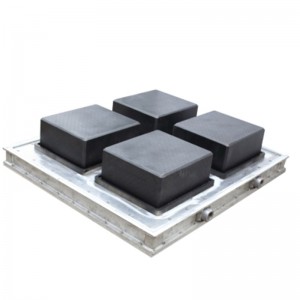

Excellent quality Eps Molding Machine - Eps Foam Insulated Concrete Block Mold – WELLEPS

Main Features 1. with good quality aluminum material 2. safe steam design. 3. Fast shape EPS products. 4. High quality production standard. Production Process We have a professional and most experienced team to design and produce EPS moulds. The mould production process: 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples ... -

-