Featured

-

-

Trending Products Etpu Foam Bike Seat Mould - EPS TV Package Mould – WELLEPS

We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less than 0... -

-

-

-

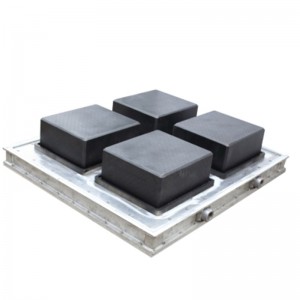

Best Price for Epp Foaming Tool For Auto Car Seat - Eps Foam Insulated Concrete Block Mold – WELLEPS

Main Features 1. with good quality aluminum material 2. safe steam design. 3. Fast shape EPS products. 4. High quality production standard. Production Process We have a professional and most experienced team to design and produce EPS moulds. The mould production process: 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples ... -

-

18 Years Factory Epp Production Line - EPS Styrofoam Raw Material For Polystyrene – WELLEPS

Description of eps raw material Expanded Polystyrene (EPS) is a light polymer. It is a foamed plastic which is added with a foaming agent by using a polystyrene resin and softened at the same time to generate a gas to form a hard closed cell structure. The uniformly closed cavity structure makes the EPS have small water absorption and good heat preservation. , light weight and high mechanical strength Products made from foamed polystyrene are nearly ubiquitous, for example packing materials,... -

Big discounting Eps Material Production Line - Eps Foam Insulated Concrete Block Mold – WELLEPS

Main Features 1. with good quality aluminum material 2. safe steam design. 3. Fast shape EPS products. 4. High quality production standard. Production Process We have a professional and most experienced team to design and produce EPS moulds. The mould production process: 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples ... -

High definition Sandwich Wall Panel Making Machine - Best Quality EPS Mould In China – WELLEPS

We have a professional and most experienced team to design and produce EPS moulds. The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment. The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm. Mould co... -

-

Personlized Products Coal Fired Boiler - Thermocol Foam Moulding Machine Fruit/Fish Boxes Packaging Making Molding Machine – WELLEPS

Main advantage: 1. Use servo drive system, the machine can work very stable. 2. Use two side steam and vacuum, machine works more efficiently. 3. With special design ejectors shelf for easy to install the moulds. Features of eps foam box machine: 1.Equipment body use the high strength steeel welded together, after the tempering process, sandblasting processing, to ensure the machne have strong structure, not get rust and increae the machine’s working life. 2.Equipment adopts Mitsubishi... -