One of Hottest for Water Tower - Best quality EPS package moulds – WELLEPS

One of Hottest for Water Tower - Best quality EPS package moulds – WELLEPS Detail:

We have a professional and most experienced team to design and produce EPS moulds.

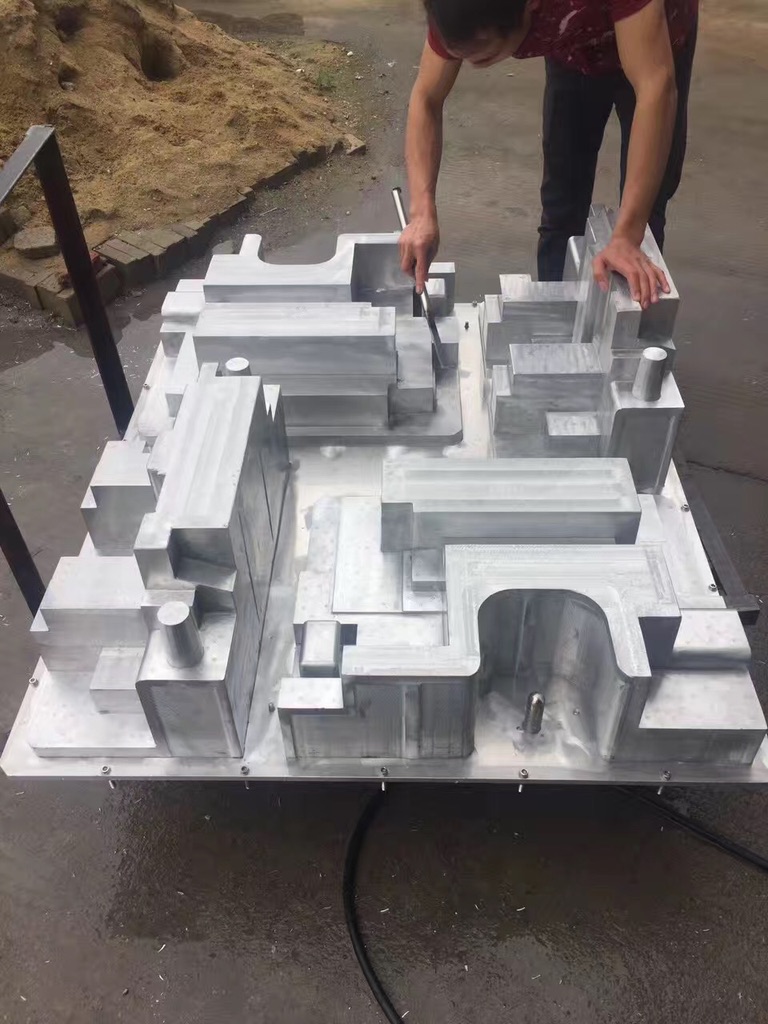

The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment.

The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm.

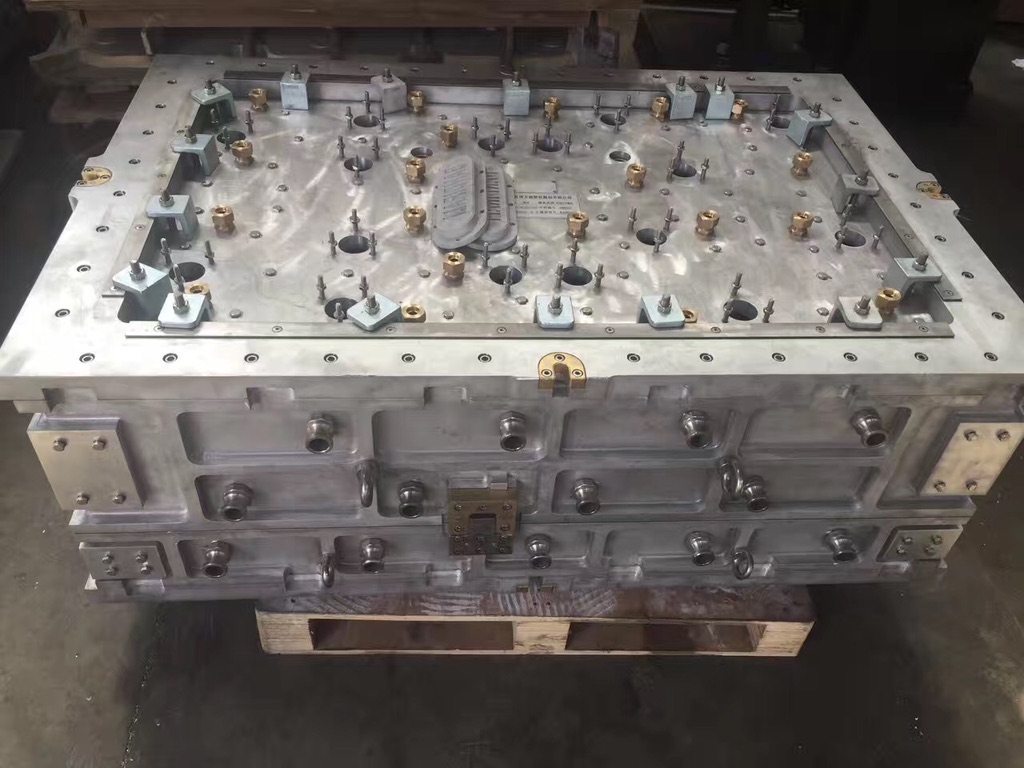

Mould coated with Teflon for better demould and the mould work smoothly in high temperature.

Mould use high standard quality 6063 aluminum.

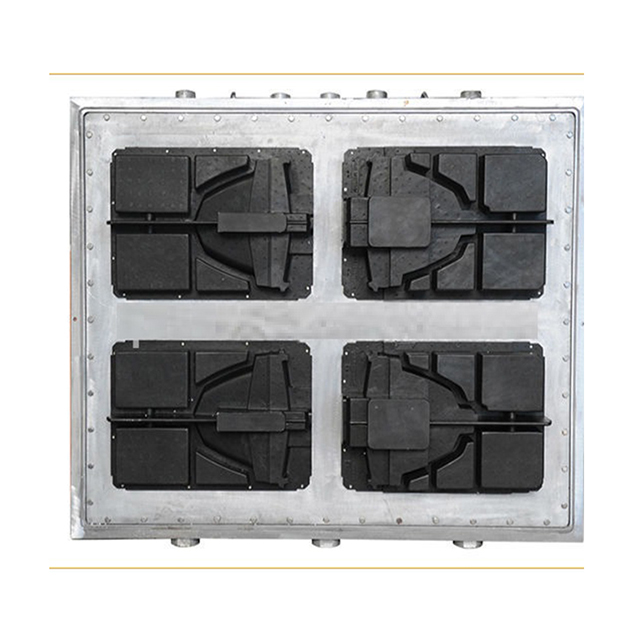

With special design for save steam and work more efficient.

We can design any kind EPS moulds according customer’s requirement. Only customers win, we can win.

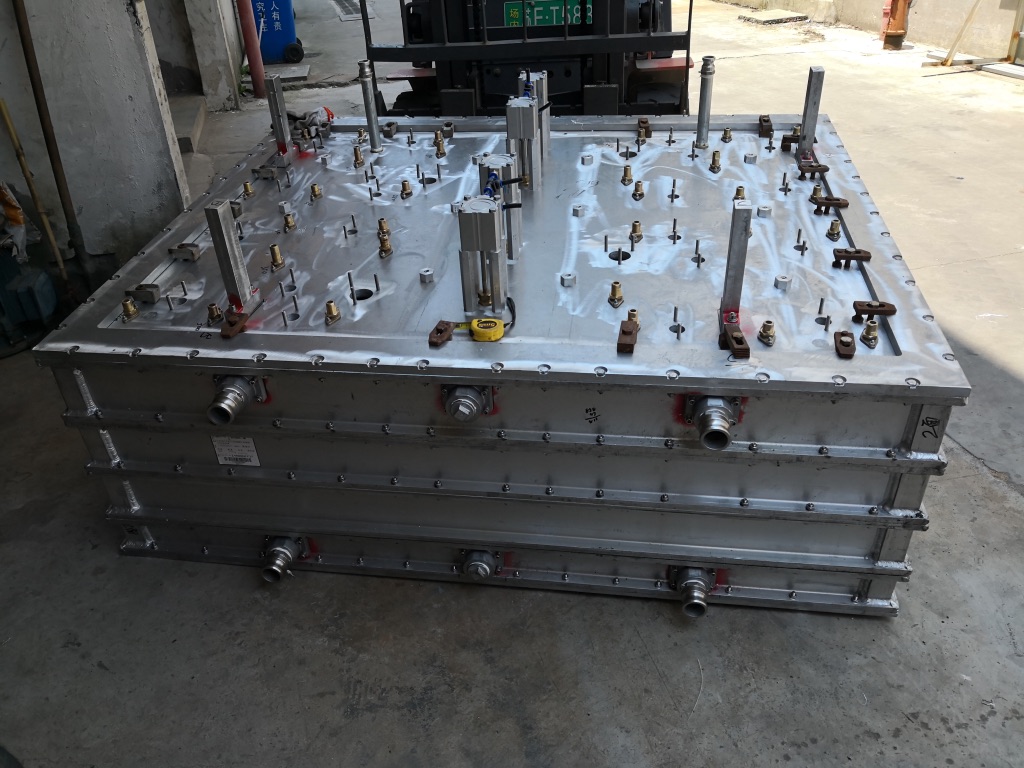

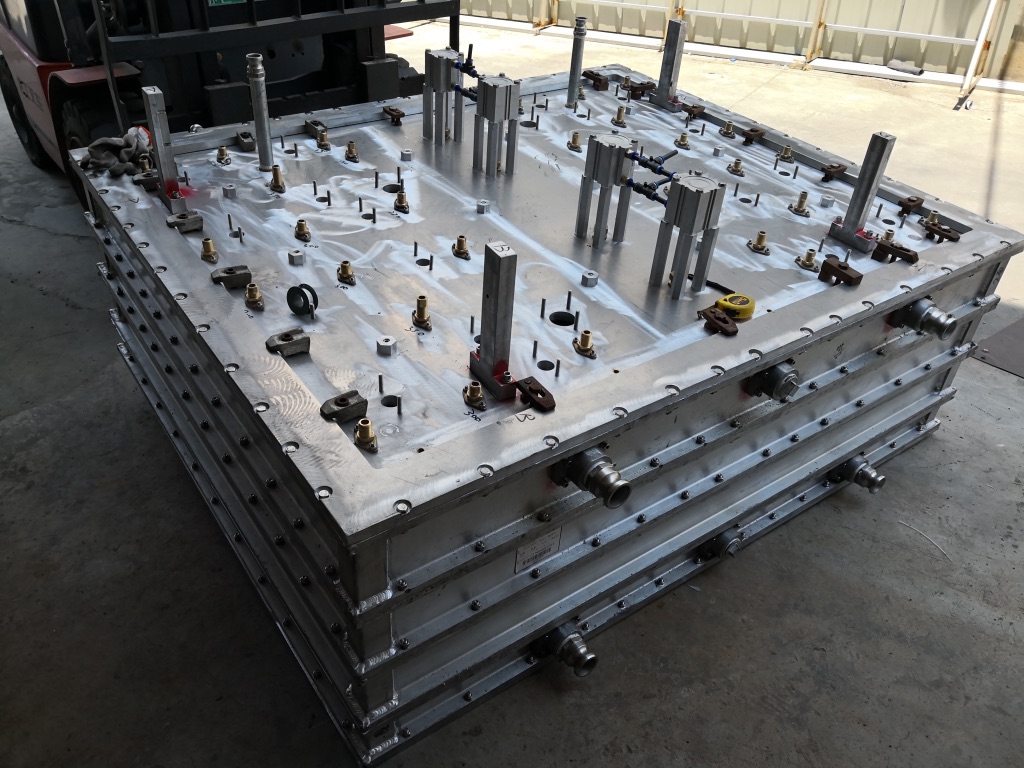

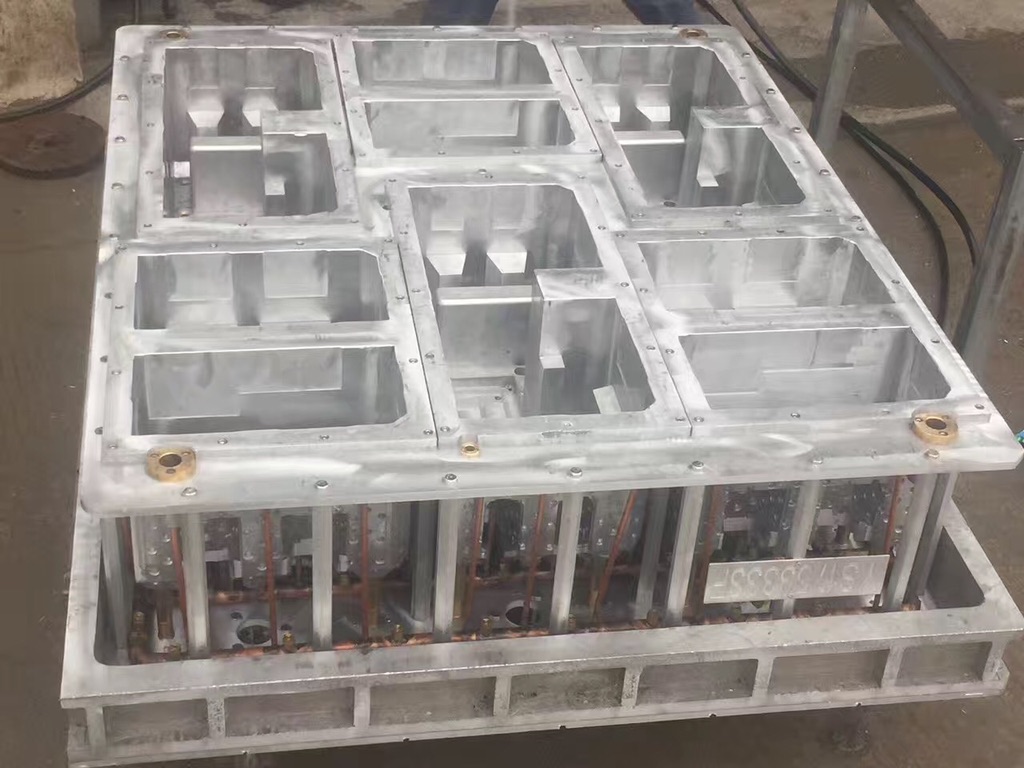

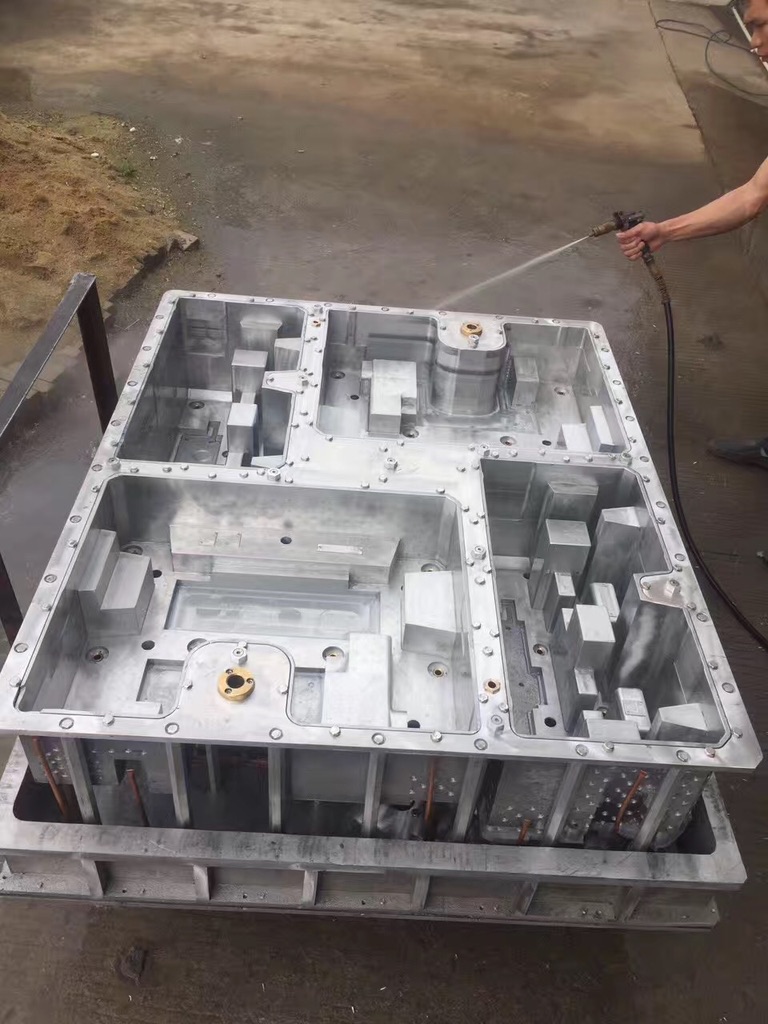

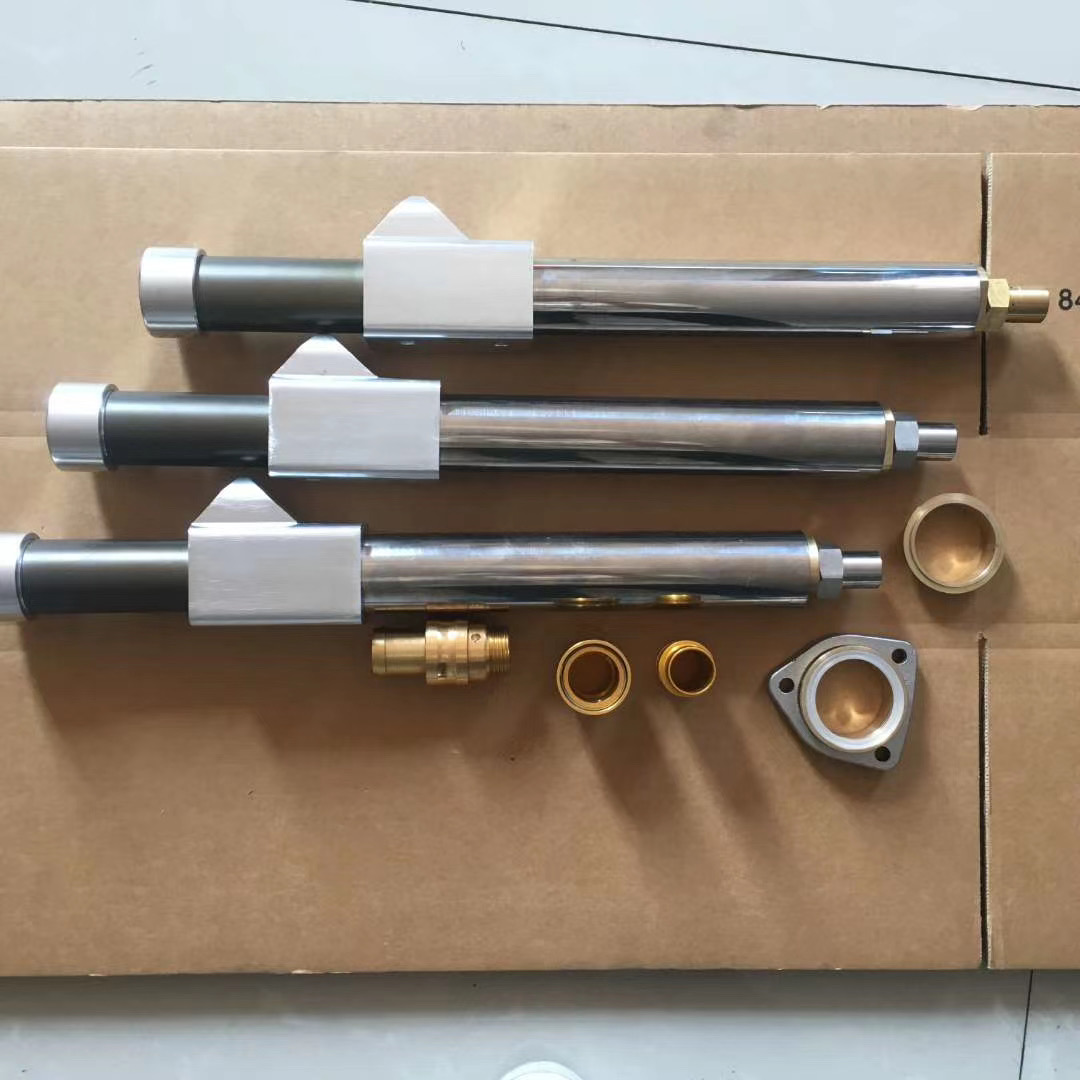

Finished moulds photos and moulds parts:

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of One of Hottest for Water Tower - Best quality EPS package moulds – WELLEPS , The product will supply to all over the world, such as: Macedonia, California, Niger, We've established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.