professional factory for Rotary Screw Compressor - Best Quality EPS Package Moulds – WELLEPS

professional factory for Rotary Screw Compressor - Best Quality EPS Package Moulds – WELLEPS Detail:

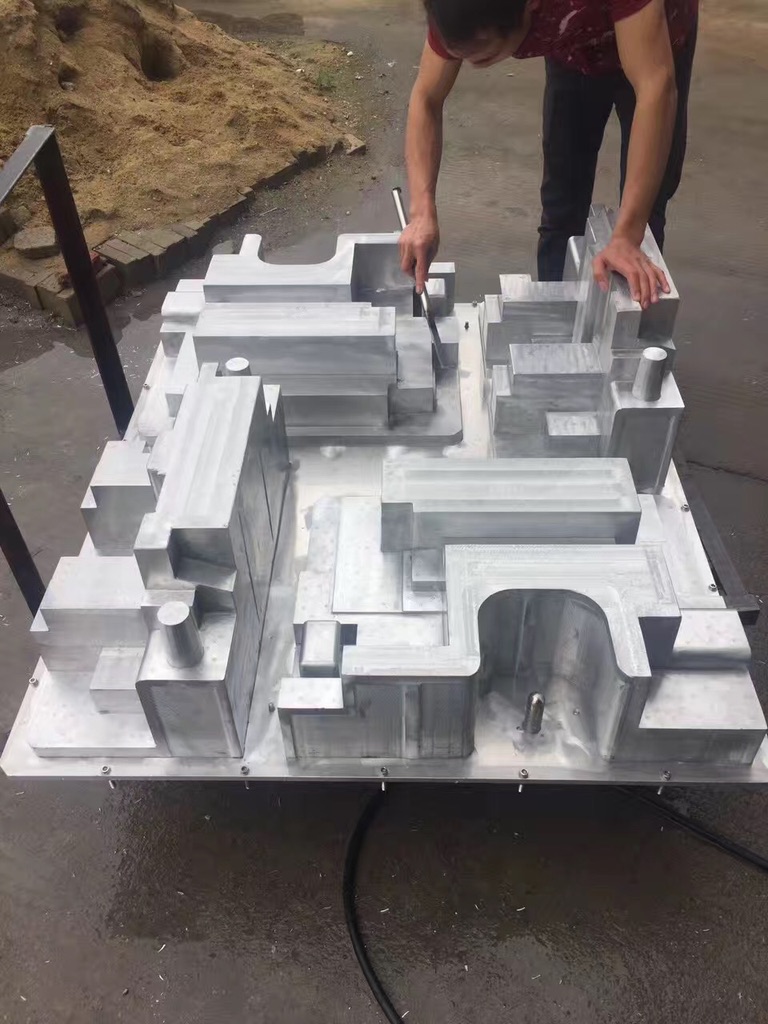

We have a professional and most experienced team to design and produce EPS moulds.

The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment.

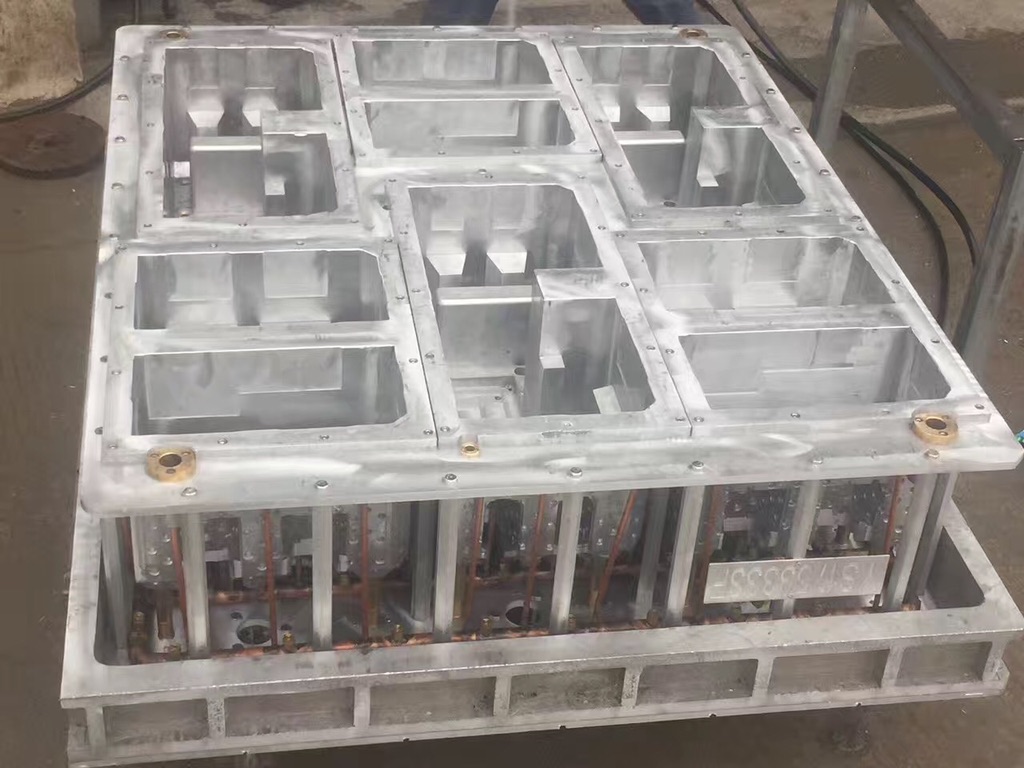

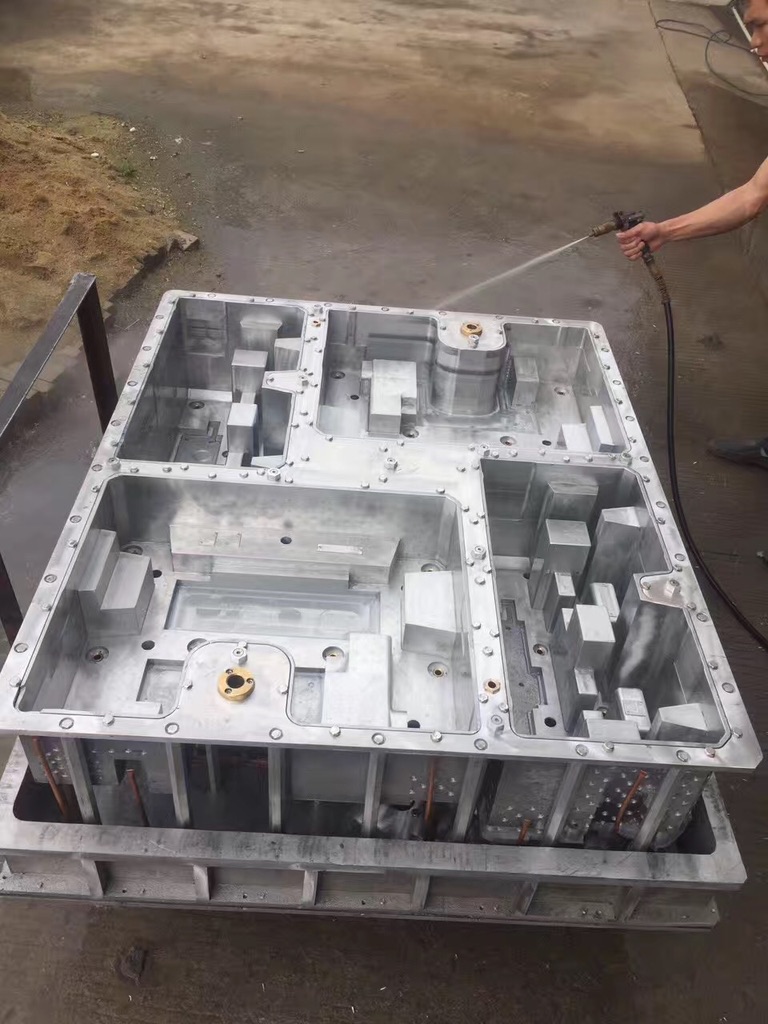

The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm.

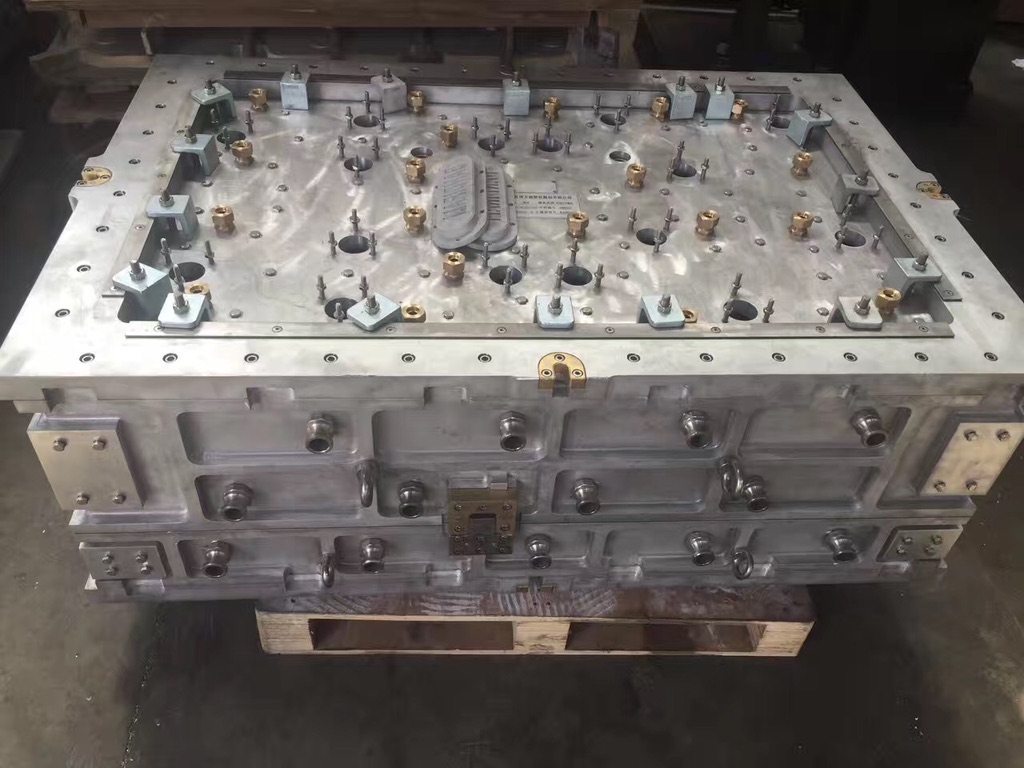

Mould coated with Teflon for better demould and the mould work smoothly in high temperature.

Mould use high standard quality 6063 aluminum.

With special design for save steam and work more efficient.

We can design any kind EPS moulds according customer’s requirement. Only customers win, we can win.

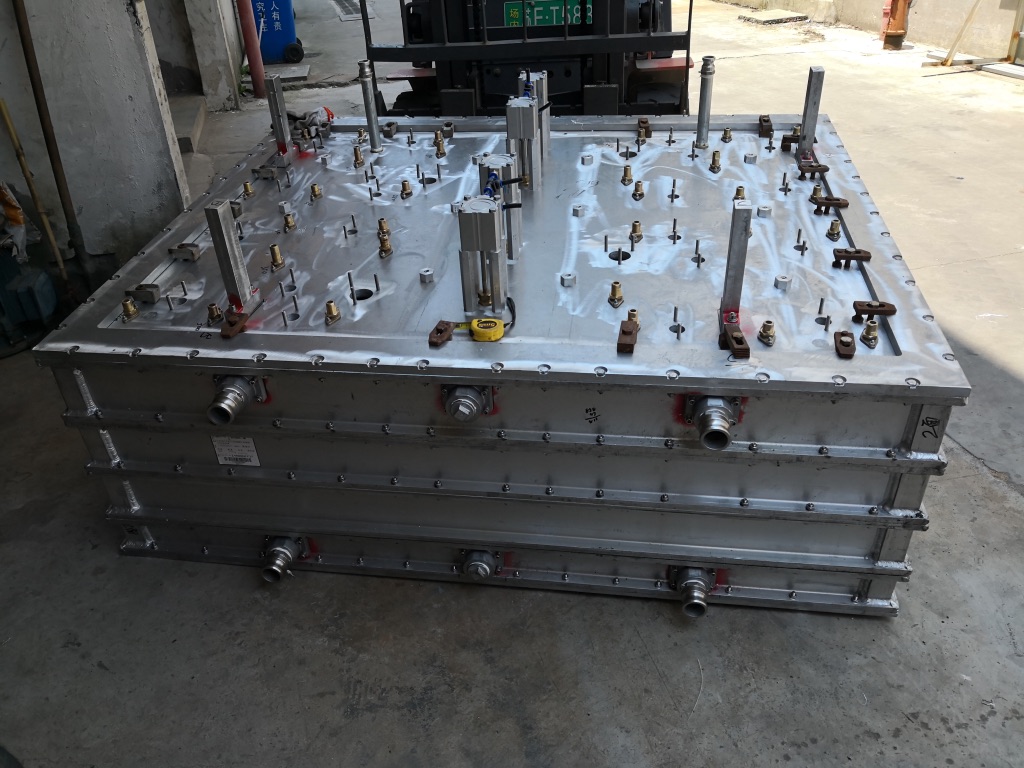

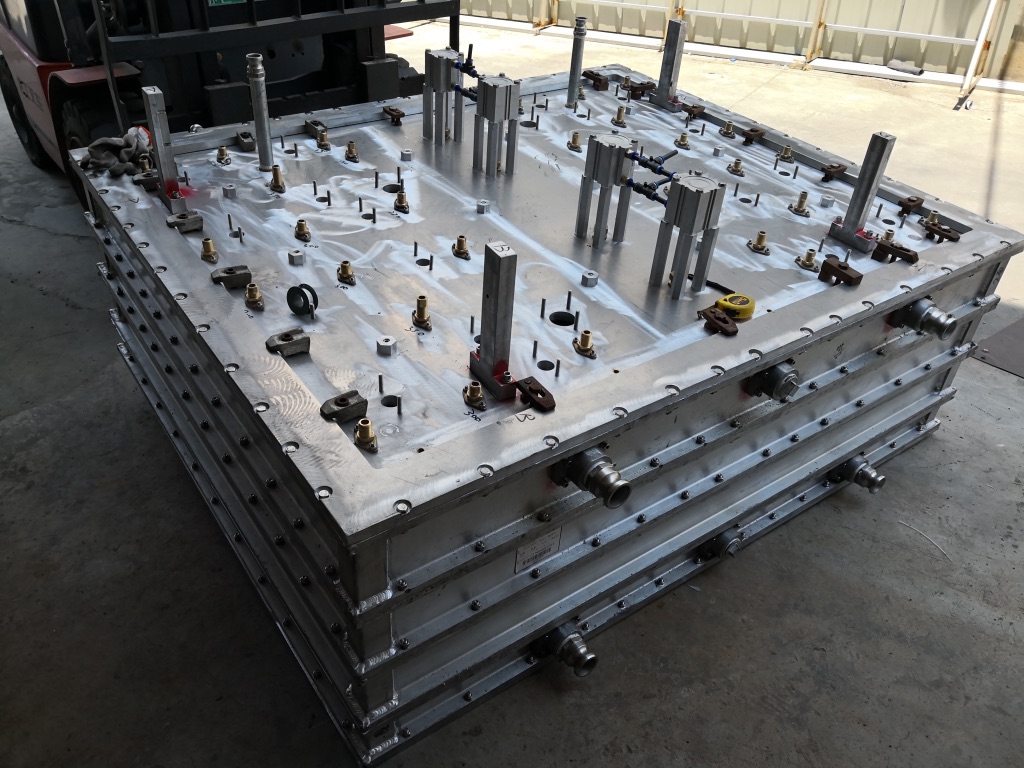

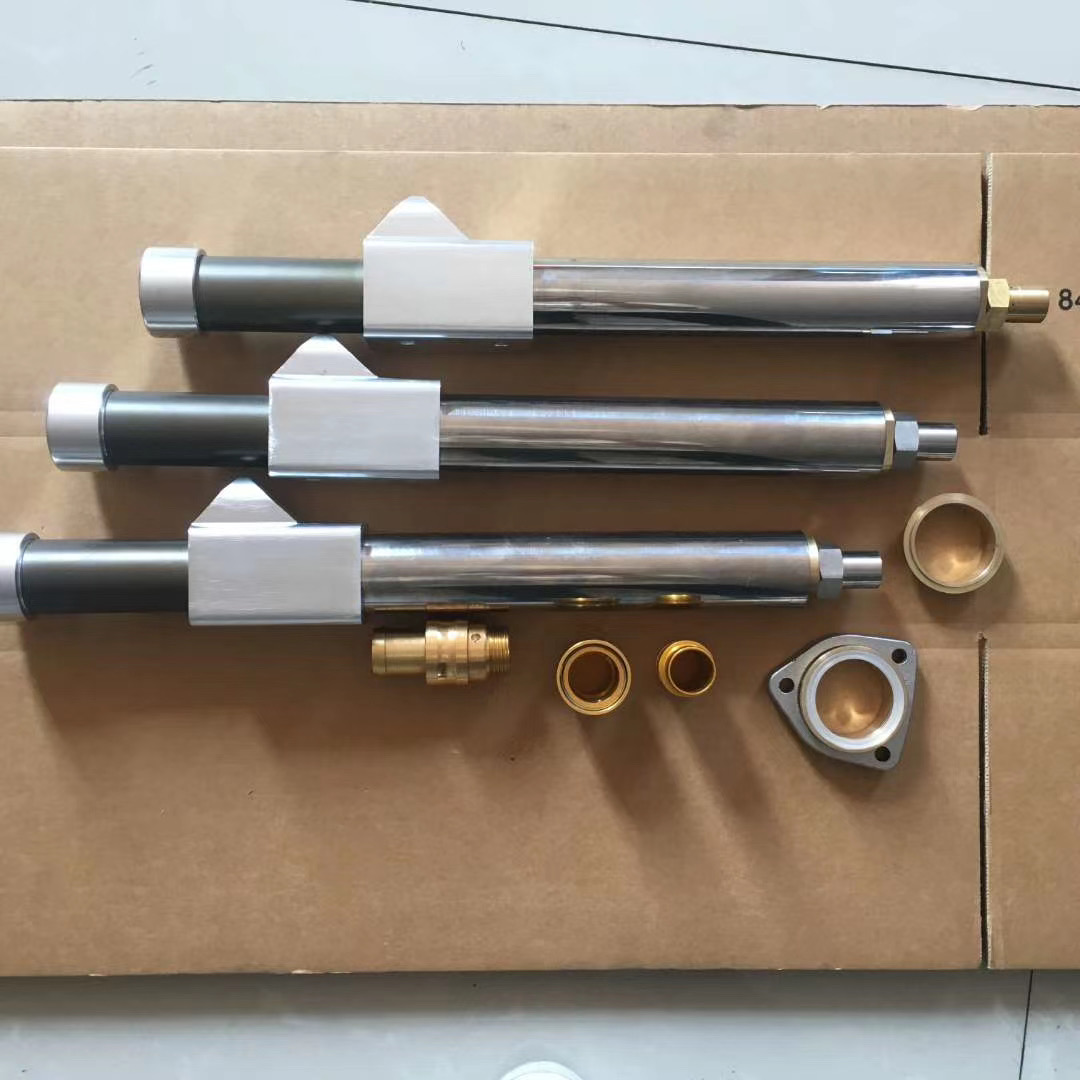

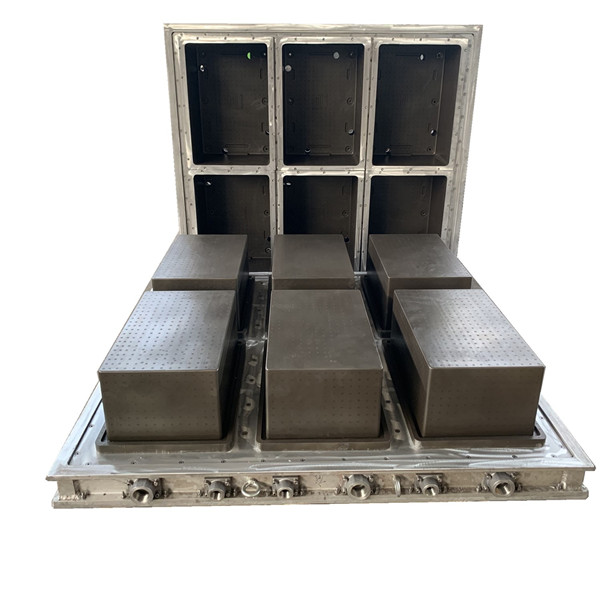

Finished moulds photos and moulds parts:

Product detail pictures:

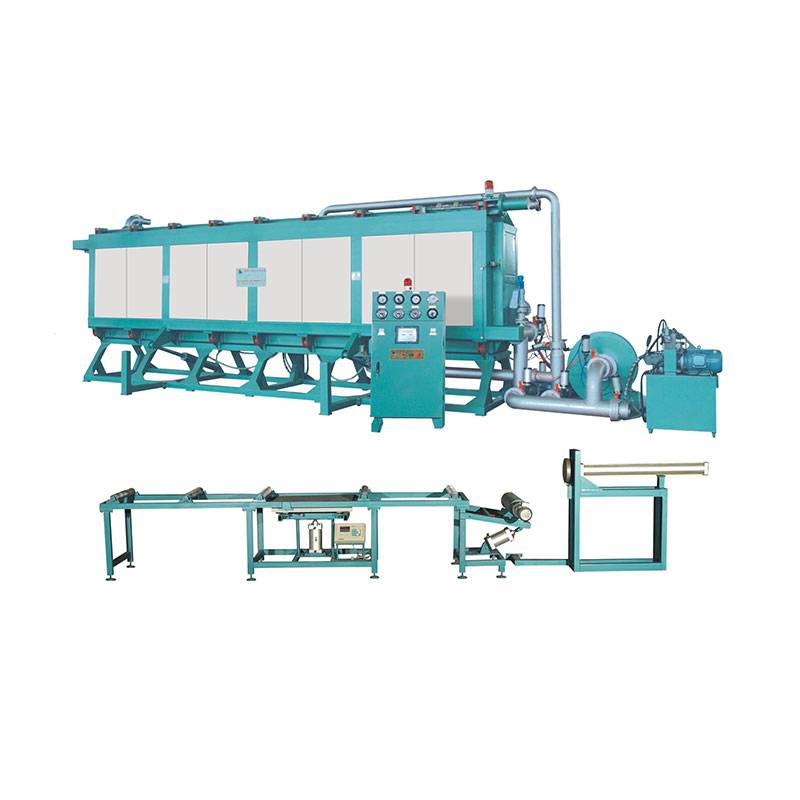

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for professional factory for Rotary Screw Compressor - Best Quality EPS Package Moulds – WELLEPS , The product will supply to all over the world, such as: Puerto Rico, Vietnam, Barbados, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!