professional factory for Rotary Screw Compressor - EPS TV package mould – WELLEPS

professional factory for Rotary Screw Compressor - EPS TV package mould – WELLEPS Detail:

We have a professional and most experienced team to design and produce EPS moulds.

The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment.

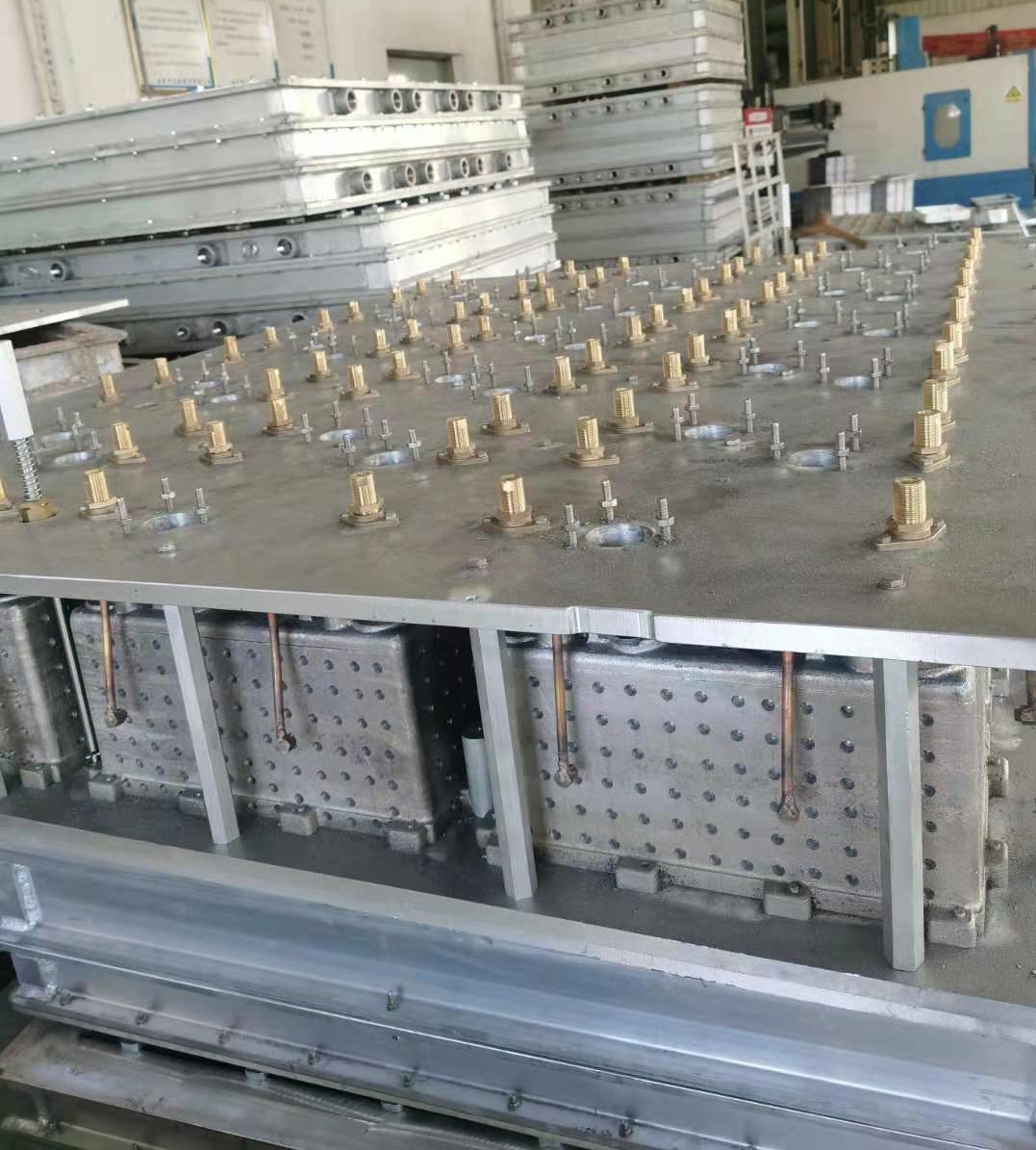

The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm.

Mould coated with Teflon for better demould and the mould work smoothly in high temperature.

Mould use high-quality aluminum alloy material.

With special design for save steam and work more efficient.

We can design any kind EPS moulds according customer’s requirement. Only customers win, we can win.

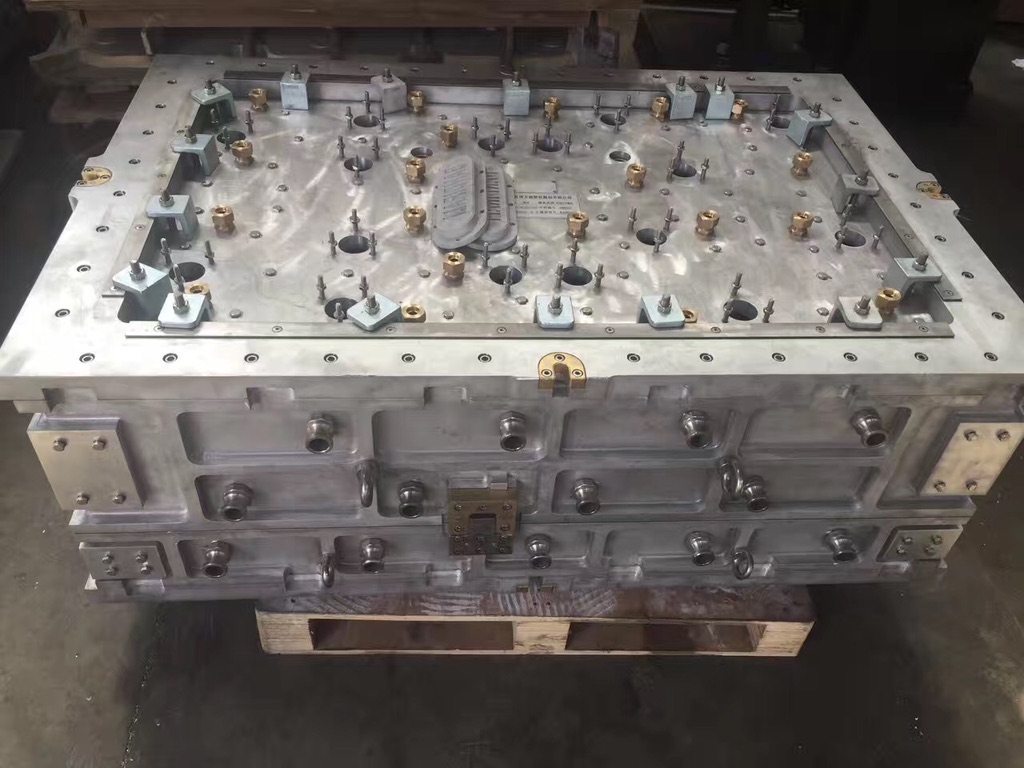

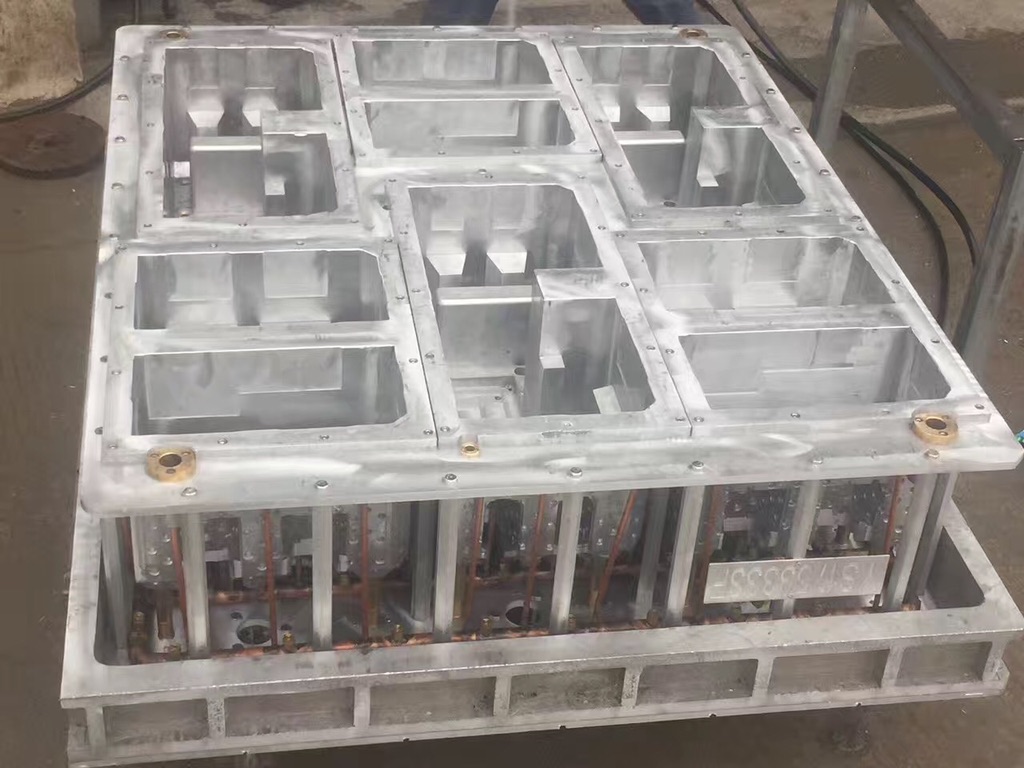

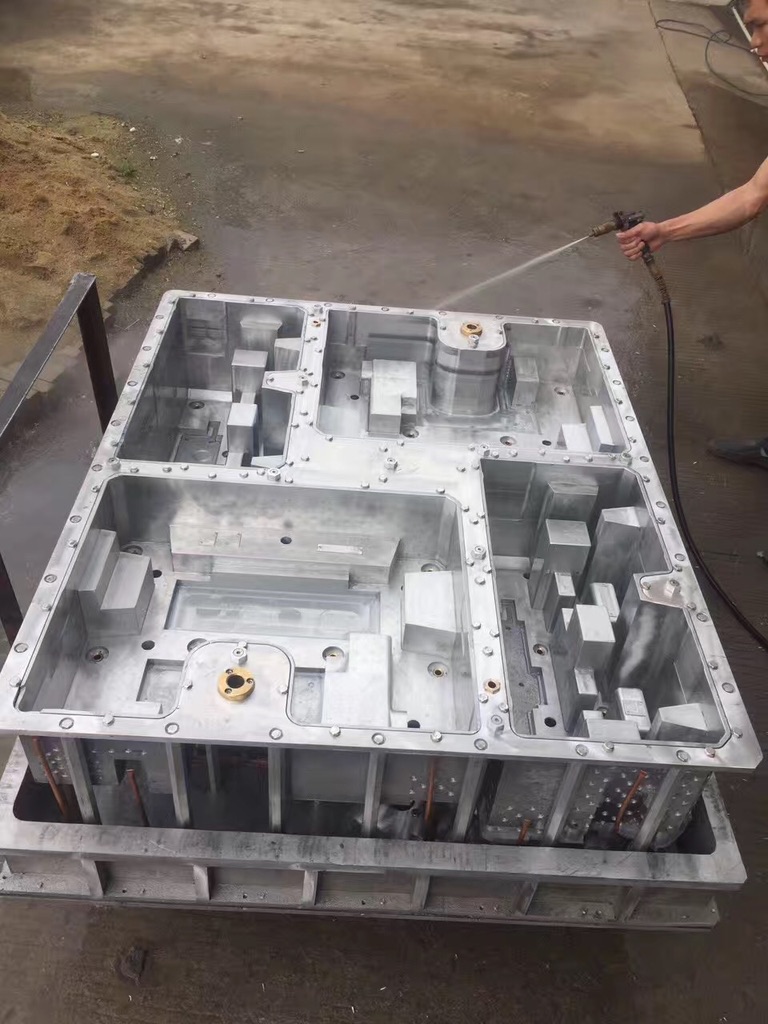

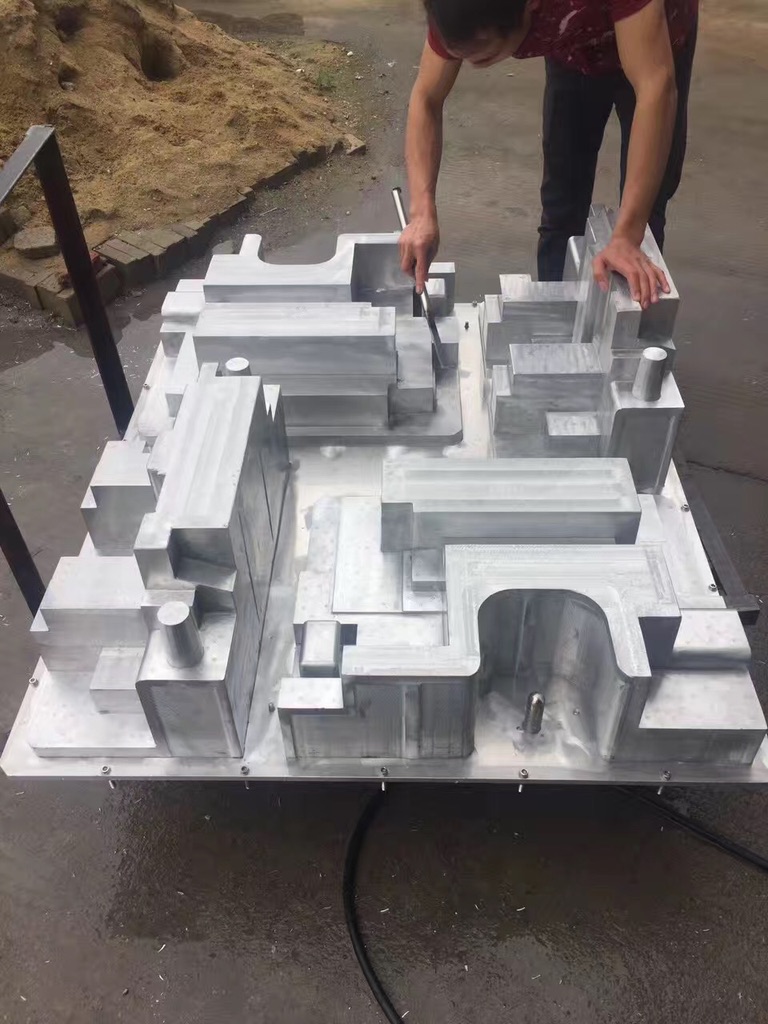

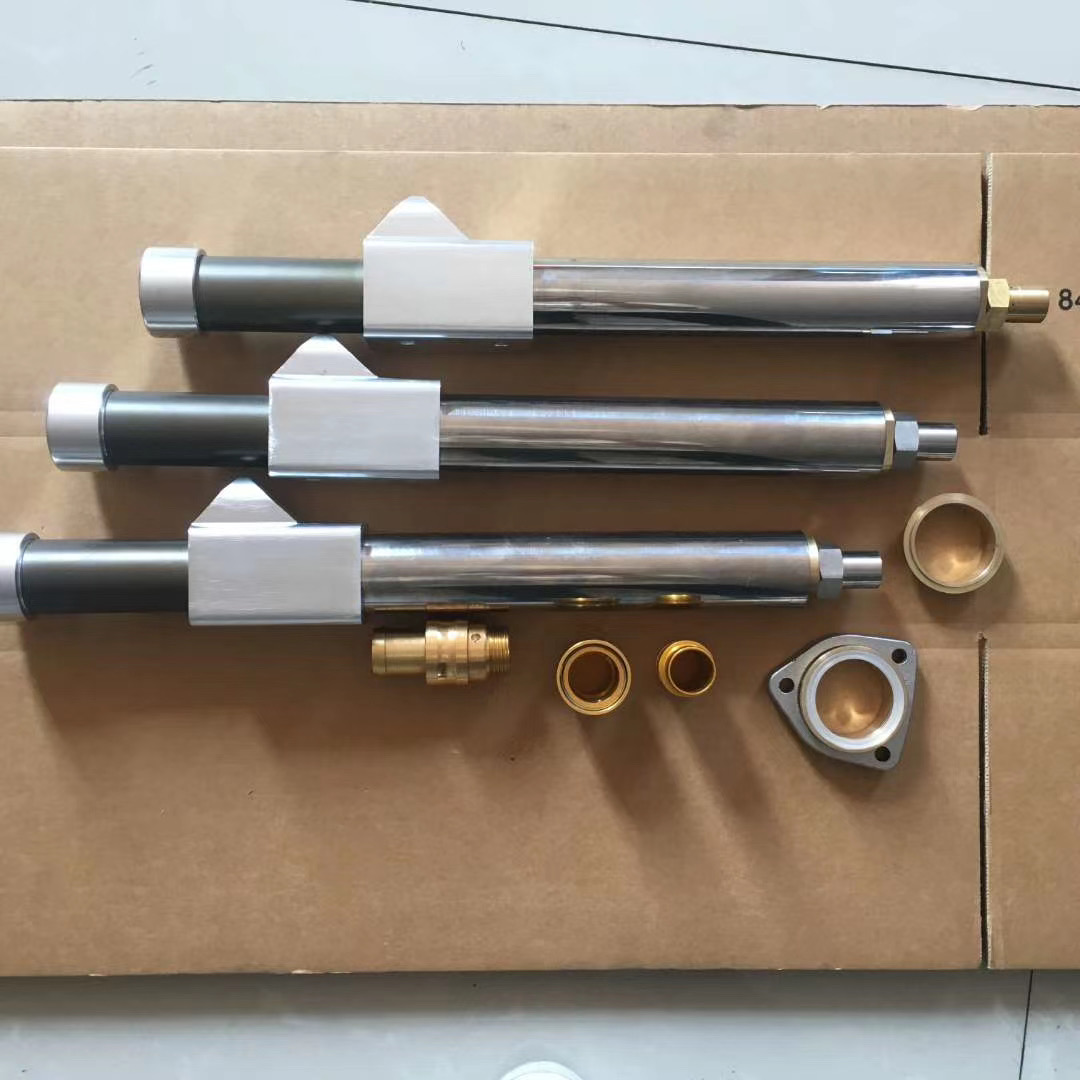

Finished moulds photos and moulds parts:

Product detail pictures:

Related Product Guide:

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for professional factory for Rotary Screw Compressor - EPS TV package mould – WELLEPS , The product will supply to all over the world, such as: Israel, Japan, Austria, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.