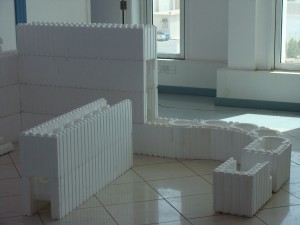

Styrofoam Dome House Kits Making Machine

Main Advantage

Styrofoam Dome House Kits Making Machine are widely used in industries such as vegetables and fish boxes, electrical parts packaging, wall and roof insulation, and house decoration.

1. Machine with strong structure.

2. Use PLC and touch screen control, run automatically.

3. High efficient vacuum to make good quality products.

4. Use different operate language, more easy to operate for workers.

5. Use good quality parts.

Machine Introduction

Precision Engineering

Our EPS Shape Moulding Machine utilizes state-of-the-art technology for precise shaping of polystyrene products. The machine ensures high accuracy and uniformity in every piece, reducing waste and increasing productivity.

High Efficiency and Output

Designed for high-speed production, our machine offers fast cycle times and robust performance, enabling you to meet tight deadlines without compromising on quality.

Customizable Solutions

We understand that every customer has unique needs. Our EPS Shape Moulding Machine can be customized with different molds and configurations to produce a wide range of shapes and sizes, catering to various market demands.

Energy-Efficient Operations

Equipped with energy-saving technology, our machine minimizes power consumption, helping you reduce operating costs and increase profitability.

Durable and Reliable

Built with high-quality materials and components, our machine is engineered for durability and long-term use, minimizing downtime and maintenance costs.

Technical Data

| Item | Unit | Type | |||||

| PSZ100T | PSZ120T | PSZ140T | PSZ160T | PSZ175T | |||

| Mould Dimension | mm | mm | 1000*800 | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 |

| Max Product Dimension | mm | mm | 850*650*330 | 1050*850*330 | 1220*1050*330 | 1420*1200*330 | 1550*1250*330 |

| Stroke | mm | 210-1360 | 210-1360 | 270-1420 | 270-1420 | 270-1420 | |

| Steam | Entry | mm | DN65 | DN65 | DN80 | DN80 | DN80 |

| Consumption | kg/cycle | (12-15T)Steam of 1T material | |||||

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 45-130 | 45-130 | 50-140 | 50-140 | 55-190 | |

| Compressed Air | Entry | mm | DN40 | DN40 | DN40 | DN50 | DN50 |

| Consumption | m3/cycle | 1.3 | 1.3 | 1.4 | 1.4 | 1.5 | |

| Vacuum Pump Capacity | m3/h | 165 | 165 | 250 | 280 | 280 | |

| Power | Kw | 11 | 11 | 14.5 | 16.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1640

*2700 |

4500*1840

*2900 |

4600*2140

*3100 |

5000*2300

*3400 |

5000*2550

*3700 |

| Weight | kg | 4100 | 4600 | 4900 | 5700 | 6200 | |

| Cycle Time | s | 60-90 | 60-100 | 60-150 | 100-180 | 120-190 | |

Applications