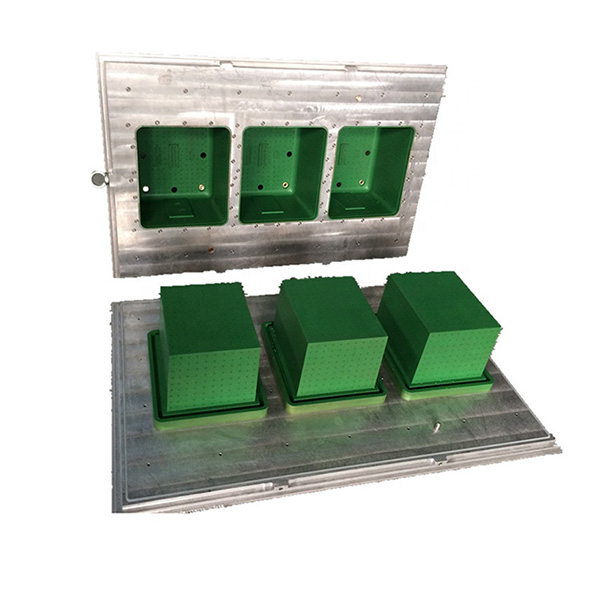

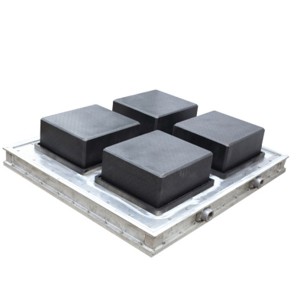

Aluminum EPS mould for foam packaging box production

Products Introduction

We have a professional and most experienced team to design and produce EPS moulds.

The mould production process is as follow 1. design the mould according customer's products drawing or samples. 2. Send mould drawing to customer for customer's confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment.

The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm.

Mould coated with Teflon for better demould and the mould work smoothly in high temperature.

Mould use high standard quality 6063 aluminum.

With special design for save steam and work more efficient.

We can design any kind EPS moulds according customer's requirement. Only customers win, we can win.

Main Advantage

1. EPS mold is made of high quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong and long lasting.

2. EPS mold are processed by CNC machines, mould sizes are precise.

3. We have strict quality control in all steps: patterning, casting, machining, assembling, Teflon coating etc.

4. We can deliver the aluminum molds quickly, test EPS molds and check samples carefully before delivery;

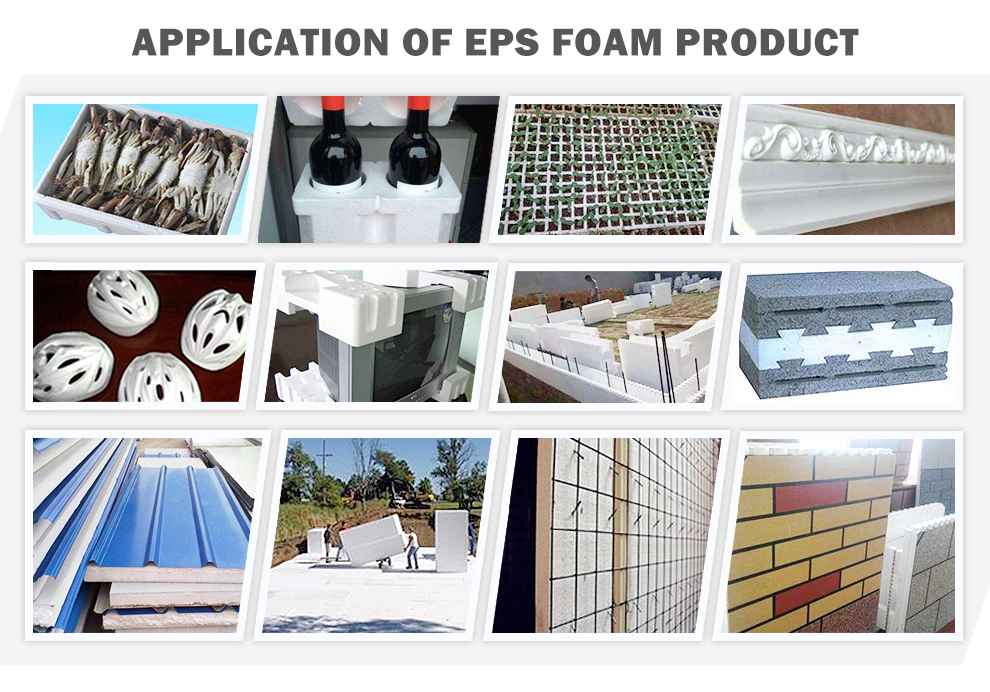

5. Our engineer have rich experience to make designs. We can design any difficult moulds for clients. Such like EPS fruit box mould, EPS cornice mould, EPS fish box mould, EPS ICF block mould, EPS seeding tray mould, all kinds of EPS electrical packaging products mould etc.

6. We can convert customer’s samples to CAD drawing or 3D drawings.

Applications