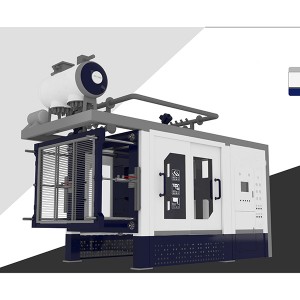

EPP foam plastic sheets surfboard shaping molds machine

product description

Processing Type: Foaming Machine

Machine Type: EPP

Voltage: 380V

Dimension(L*W*H): 5000*2450*3500

Power (kW): 7.5

Weight (KG): 7500 KG

Warranty: 1 Year

Applicable Industries: Building Material Shops, Manufacturing Plant, Construction works

Core Components: Motor, Pump, PLC

Product Name: EPP Foam Shaping Machine

Application area: Package,EPP toys,EPP high-end car parts

Certification: CE

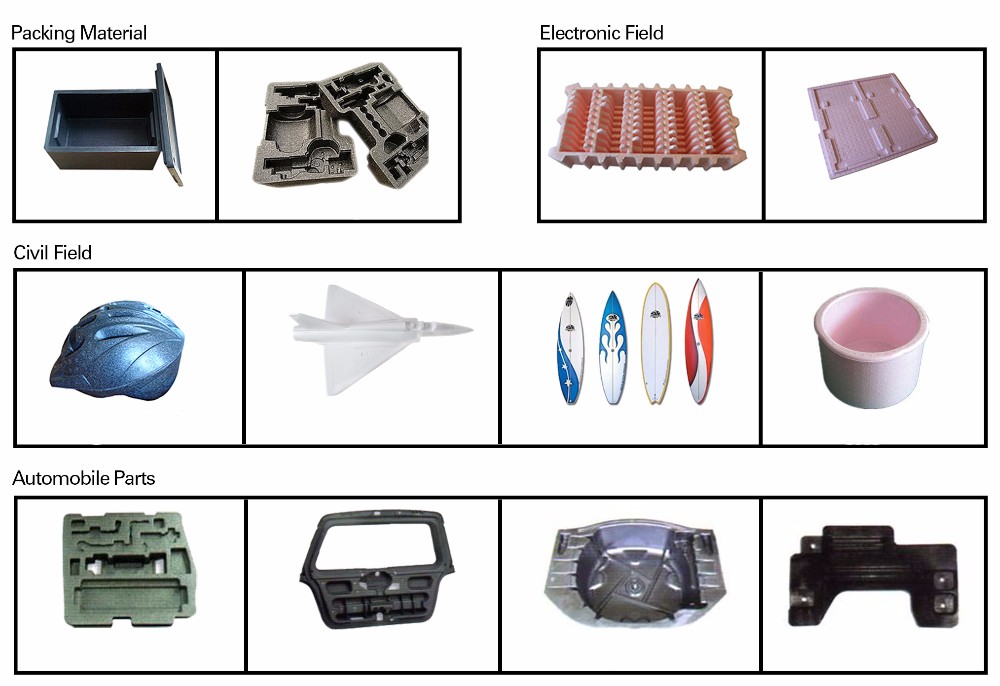

EPP Vacuum System Shape Moulding Machine is used to produce all kinds of valuables EPP packaging (such as notebook computers, liquid crystal displays, precision instruments), EPP toys (airplane models), EPP high-end car parts (EPP bumper, EPP toolbox, EPP sunshade etc.), EPP sporting goods (Surfboard, helmet, etc.)

Main Features

1. Solid steel construction processed by high temperature annealing, heat treatment, surface de-rusted by sandblast and sprayed by anti-corrosive paint.

2. Control system adopts Japan PLC and English touch screen for easy operating and fully automatic producing.

3. High quality and stable machines parts, like German Burkert angle-seat valves.

4. Energy saving by well-designed machine size, pipe lines to realize fast steam pressure increasing and decreasing.

5. High flow hydraulic drive with double hydraulic cylinder, which makes machine running steadily and locking tightly.

5. The machine can be equipped with a build-in vacuum system, and also there is an access to center vacuum system.

6. Double feeding chamber for fast feeding to shorten the cycle time.

7. Balance valve for stable steam controlling.

8. Extended zinc coated machine legs are optional for customer for installing machine on special ground.

9. Machine legs and platform is optional.

Technical Data

| Item | Unit | Type/Technical Data | ||

| PSZ1214EP | PSZ1218EP | |||

| Mould Dimension | mm | 1500*1300 | 1950*1300 | |

| Max.Product Dimension | mm | 1400*1200*330 | 1800*1200*330 | |

| Minimum Mould Thickness | mm | 220 | 220 | |

| Stroke | mm | 210-1450 | 210-1450 | |

| Mounting Interface | Raw material | / | DN40 | DN40 |

| Steam | / | DN100 | DN100 | |

| Compressed air | / | DN65 | DN65 | |

| Cooling water | / | DN80 | DN80 | |

| Drainage | / | DN150 | DN150 | |

| Ventilation | / | DN80 | DN80 | |

| Consumption | Steam | Kg/cycle | 6-13 | 10-15 |

| Compressed air | m3/cycle | 1.3 | 1.5 | |

| Cooling water | Kg/cycle | 60-100 | 150-180 | |

| Connected load | Hydralic motor | Kw | 7.5 | 7.5 |

| Vacuum pump | Kw | 5.5 | 7.5 | |

| Appr.machine weight | Kg | 5700 | 7500 | |

| Overall dimension | mm | 4600×2140 ×3100 | 5000×2450 ×3500 | |

Products