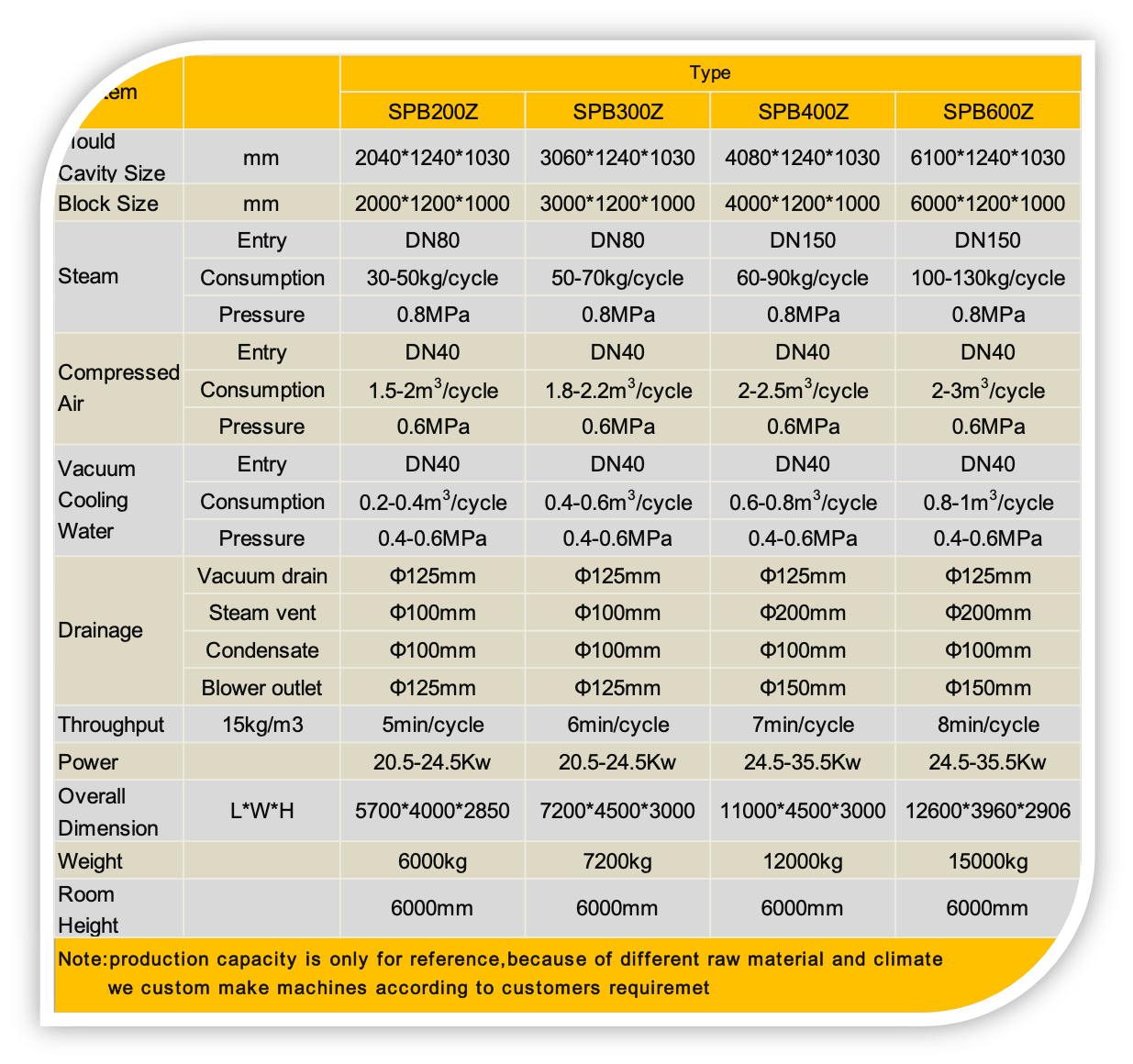

Fast delivery Lightweight Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS

Fast delivery Lightweight Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS Detail:

Main Features

1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power and energy saving design. Produced blocks have excellent cohesiveness, low moisture content, to ensure every customer’s satisfy.

4. Adopt PLC and touch screen control system, equipped with material level sensor can realize automatic control of feeding, equipped with foam pressure sensor control cooling time automatically.

5. Machine use good quality electrical, pneumatic components, valves and other parts. And the parts with international standard, so customer is easy to find replacement at local.

6. Machine adopts hydraulic pressure station to be the center control system. Use hydraulic open door, ejector de-mould and locking, guarantee the machine running smoothly, stable performance.

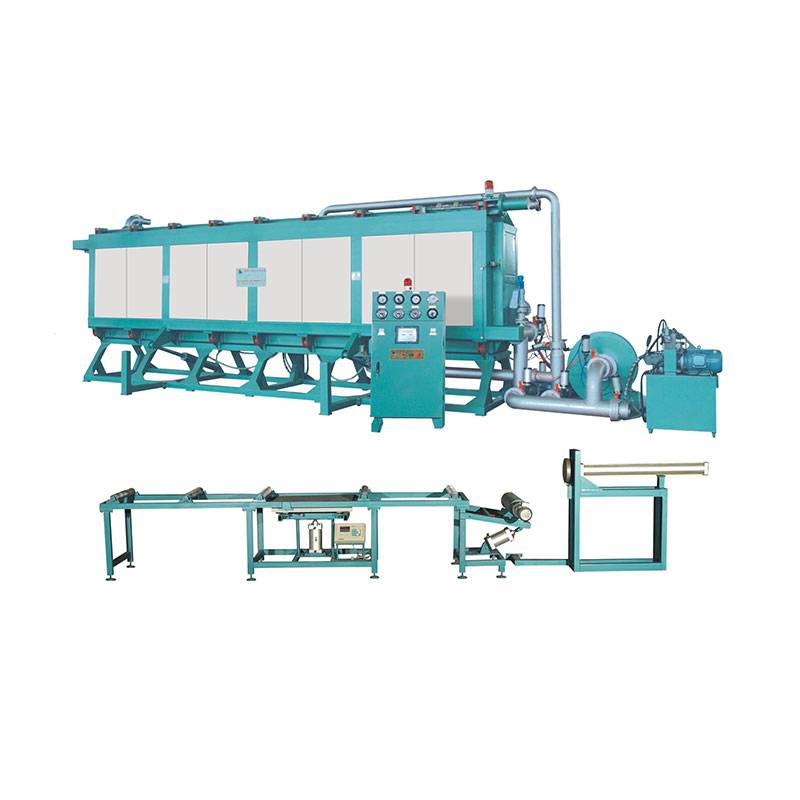

EPS block Machine in workshop :

EPS block Machine loading container:

EPS Products:

Remarks:

Above equipment has FT and ZT model

FT type is air-cooling type, cooling without c vacuum system

FT type products thickness is 600 mm.

ZT products maximum thickness is 1000 mm.

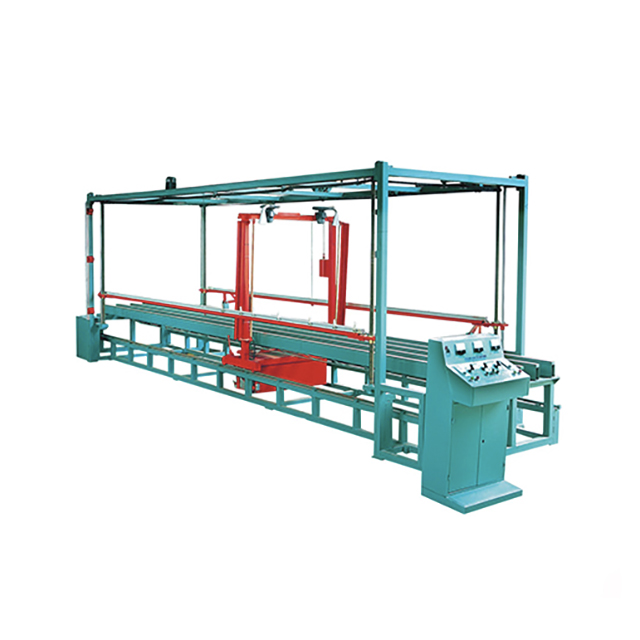

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Fast delivery Lightweight Panel Production Line - High efficient EPS Vacuum Block Moulding Machine – WELLEPS , The product will supply to all over the world, such as: Cancun, Uruguay, Spain, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.