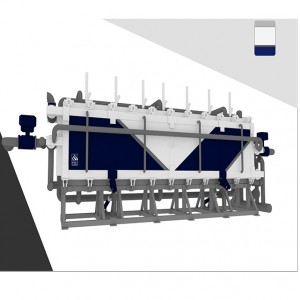

SPB200TF-600TF Polystyrene EPS Block Molding Machine Air Cooling Equipment

Description

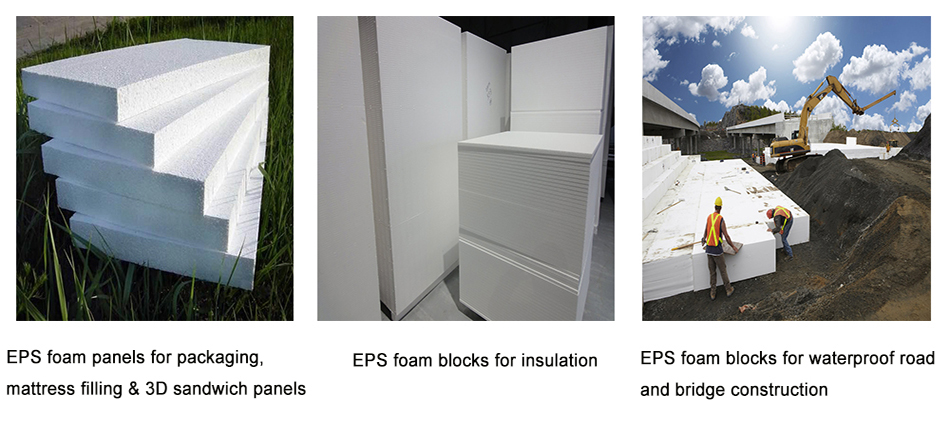

Air Cooling EPS Block Moulding Machine is used to make EPS blocks, then cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

It makes eps foam beads to big foam block through steam heating and air cooling. With PLC and touch screen to realize full automatic production for feeding, heating, vacuum cooling, mould opening, mould closing and ejecting the foam block

Main Features

1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power and energy saving design. Produced blocks have excellent cohesiveness, low moisture content, to ensure every customer’s satisfy.

4. Adopt PLC and touch screen control system, equipped with material level sensor can realize automatic control of feeding, equipped with foam pressure sensor control cooling time automatically.

5. Machine use good quality electrical, pneumatic components, valves and other parts. And the parts with international standard, so customer is easy to find replacement at local.

6. Machine adopts hydraulic pressure station to be the center control system. Use hydraulic open door, ejector de-mould and locking, guarantee the machine running smoothly, stable performance.

Technical Data

| Item | Type | ||||

| SPB200TF | SPB300TF | SPB400TF | SPB600TF | ||

| Mould Cavity Size | mm | 2040*1240-940*630 | 3060*1240-940*630 | 4080*1240-940*630 | 6100*1240-940*630 |

| Block Size | mm | 2000*1200-900*600 | 3000*1200-900*600 | 4000*1200-900*630 | 6000*1200-900*600 |

| Steam | Entry | DN150 | DN150 | DN150 | DN200 |

| Consumption | 20-30kg/cycle | 30-40kg/cycle | 45-55kg/cycle | 60-70

kg/cycle |

|

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN40 | DN40 | DN50 | DN65 |

| Consumption | 1-1.5m3/cycle | 1.5-1.8m3/cycle | 1.8-2m3/cycle | 2-2.3

m3/cycle |

|

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Vacuum drain | ||||

| Steam vent | Φ100mm | Φ100mm | Φ200mm | Φ200mm | |

| Condensate | |||||

| Blower outlet | Φ100mm | Φ100mm | Φ150mm | Φ150mm | |

| Throughput | 15kg/m3 | 7-12min/cycle | 8-15min/cycle | 8-18min/cycle | 8-18min/cycle |

| Power | 14.5Kw | 14.5Kw | 18.5Kw | 18.5Kw | |

| Overall Dimension | L*W*H | 4000*2150*2120 | 5030*2270*2120 | 6040*2270*2250 | 8100*2500

*3100 |

| Weight | 6000kg | 7500kg | 12000kg | 15000kg | |

| Room Height Required | 6000mm | 6000mm | 6000mm | 6000mm | |

Applications