High Quality SPJ90-160 EPS Styrofoam Making Beads Machine Pre-expander

Machine Introduction

EPS Styrofoam Beads Making Machines is widely used for high density and middium capacity of EPS foam beads production line.

1. Fully automatic production.

2. Controlled by touch screen and PLC, easy to operate.

3. High output and save energy.

4. Exact density of foam beads.

5. Stable quality and less failure.

Main Features

1.Feeding, expander, filtrating, transport to silos automatically

2.Steam system: The Styrofoam batch expander machine has steam pressure reducer and angle valve to control steam. The steam system allows Styrofoam batch expander machine to operate properly and produce high quality foaming beads.

3.Filling system: The EPS pre-expander machine adopts electronic weighing system,material level sensor control, so as to control capacity of foaming materials, to ensure that the foam bead evenly

4.Electric control: Adopt PLC and touch screen, achieve precise automatic operation

5.Feed barrels made of stainless steel. Electrical components, valves are used abroad well-known brands, to maintain the durable, stable performa

Technical Data

| Item | Type | ||||

| SPJ90 | SPJ110 | SPJ150 | SPJ160 | ||

| Expansion Chamber | Diameter | Φ900mm | Φ1100mm | Φ1500mm | Φ1600mm |

| Volume | 0.85m3 | 1.4m3 | 4.5m3 | 5.4m3 | |

| Useable Volume | 0.6m3 | 0.9m3 | 3.2m3 | 4.5m3 | |

| Steam | Entry | DN40 | DN50 | DN40 | DN100 |

| Consumption | 2-4kg/cycle | 6-9kg/cycle | 15-18kg/cycle | 18-20kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN25 | DN25 | DN50 | DN40 |

| Consumption | 0.3m3-0.4m3/cycle | 0.5m3-0.6m3/cycle | 0.5-0.6m3/cycle | 0.5m3-0.8m3/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Drainage Port | DN100 | DN80 | DN100 | DN150 |

| Condensate | DN40 | DN80 | DN40 | DN50 | |

| Throughput | 13g/l 240kg/h | 12g/l 240kg/h | 12g/l 600kg/h | 12g/l 1500

kg/h |

|

| 18g/l 350kg/h | 15g/l 320kg/h | 15g/l 900kg/h | 15g/l 2000

kg/h |

||

| 25g/l 480kg/h | 20g/l 430kg/h | 20g/l 1200kg/h | 20g/l 26000

kg/h |

||

| 31g/l 590kg/h | 30g/l 600kg/h | 30g/l 1500kg/h | 30g/l 3100

kg/h |

||

| 50g/l 720kg/h | |||||

| Material Conveying Line | Φ150mm | Φ150mm | Φ150mm | Φ250mm | |

| Power | 16.75Kw | 16.13Kw | 24.85Kw | 38.45Kw | |

| Density | 12-90g/l | 12-30g/l | 12-30g/l | 12-30g/l | |

| Density Tolerance | ≤±2% | ≤±3% | ≤±5% | ≤±3% | |

| Overall Dimension | L*W*H | 4500*2000*4900 | 5600*3800*4530 | 4310*4150*5120 | 11000*2840

*6050 |

| Weight | 2500kg | 3500kg | 5000kg | 8000kg | |

| Room Height Required | 5000mm | 5000mm | 6000mm | 7000mm | |

| Auto density-weighing system | optional | optional | optional | ||

| Second expansion | include | optional | |||

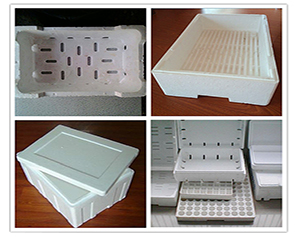

Products